The engineering sophistication and operational versatility of modern telescopic handler attachments have revolutionized material handling practices across construction, agriculture, manufacturing, and logistics sectors. These specialized tools transform standard telescopic handlers into adaptable machines capable of performing diverse functions that would traditionally require multiple pieces of dedicated equipment.

Telescopic handler attachments leverage the unique operational characteristics of these machines—impressive reach, variable height positioning, and exceptional manoeuvrability—while adding task-specific capabilities that address particular handling challenges. This integration of core machine functionality with specialized attachment features creates handling solutions that combine efficiency, precision, and safety across a wide range of applications.

The comprehensive ecosystem of telescopic handler attachments includes solutions for virtually every material handling scenario:

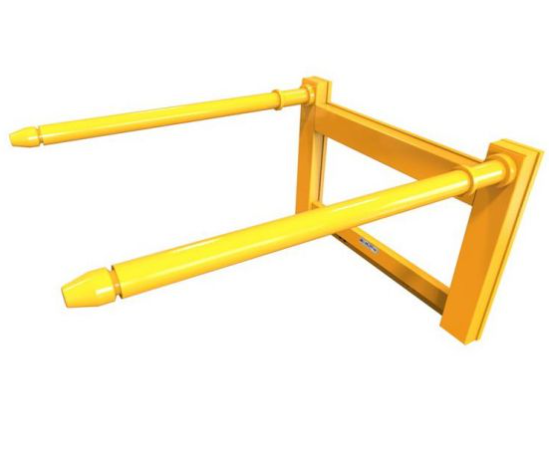

- Precision Load Manipulation: Rotators, positioners, and specialized clamps for exact load placement

- Bulk Material Handling: Buckets, grapples, and high-capacity forks for efficient material movement

- Extended Reach Operations: Jibs, truss booms, and specialized extensions for accessing difficult positions

- Personnel Elevation: Work platforms with integrated safety systems for elevated operations

- Specialized Industry Tools: Purpose-designed attachments for specific sectors including construction, agriculture, and waste management

The operational advantages of implementing quality telescopic handler attachments extend beyond simple versatility:

- Enhanced productivity through rapid attachment changes between different operational functions

- Improved return on investment by expanding the capabilities of existing equipment

- Reduced capital expenditure compared to purchasing dedicated machines for specialized tasks

- Decreased training requirements with operators becoming proficient on a single base machine

- Lower maintenance and storage costs compared to maintaining multiple equipment types

Each telescopic handler attachment undergoes rigorous engineering to ensure operational safety, structural integrity, and compatibility with specified machine parameters. High-grade materials, precision manufacturing, and comprehensive testing result in attachments that deliver reliable performance even in demanding operational environments.

For organizations seeking to optimize their equipment assets while maintaining operational flexibility, quality telescopic handler attachments provide an engineered solution that transforms a single machine into a versatile handling system. Explore our comprehensive range and discover how these specialized tools can enhance your telescopic handler's capabilities while reducing overall equipment costs.