Equipment skates provide specialized low-profile transportation solutions designed for efficient movement of substantial loads including machinery, equipment, safes, cabinets, and other heavy items that present significant handling challenges. Hall-Fast offers a comprehensive range of professional-grade skates engineered to facilitate controlled movement of heavy objects across industrial, commercial, maintenance, and installation environments without requiring permanent lifting equipment or extensive manual handling.

These versatile transport systems enable precise positioning of substantial items while maintaining minimal height clearance, creating practical handling solutions for environments where overhead space limitations, doorway restrictions, or installation constraints prevent the use of conventional lifting equipment. For operations requiring efficient movement of heavy components with minimal elevation, skates deliver significant operational advantages through their innovative low-profile design.

Low-Profile Load Movement Capability

The defining characteristic of equipment skates is their minimal height design that enables heavy object transportation with the absolute minimum elevation necessary for mobility. This low-profile configuration provides particular advantages when handling:

- Heavy machinery requiring doorway clearance during installation

- Industrial equipment with overhead space constraints

- Safes and security cabinets requiring precise positioning

- Manufacturing equipment during facility reconfiguration

- Substantial furniture pieces in commercial environments

- Server cabinets and IT infrastructure during installation

- Production equipment during plant reorganization

The minimal elevation maintains clearance for restricted-height transportation while providing the mobility necessary for efficient repositioning throughout facilities with diverse spatial constraints.

Enhanced Load Distribution Technology

Professional equipment skates incorporate advanced load distribution engineering that enables substantial weight capacity despite their compact dimensions. This sophisticated weight management spreads concentrated loads across precisely designed contact surfaces and multiple roller systems, creating stable transportation platforms capable of supporting weights that far exceed what their size might suggest.

This load distribution capability enables controlled movement of extremely heavy items using relatively compact equipment, maintaining practical handling solutions for substantial objects without requiring oversized transportation systems that might create their own operational challenges through excessive dimensions or weight.

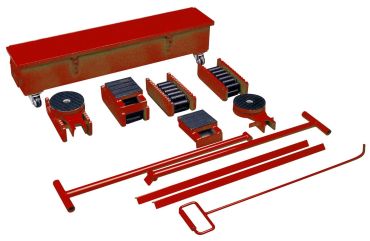

Versatile Configuration Options

Recognizing the diverse requirements of different material handling operations, Hall-Fast offers equipment skates in various configurations designed for specific applications and operational contexts. Available systems include:

- Machine skates for general industrial applications

- Steerable skate systems for enhanced directional control

- Swivel skate designs for complex movement patterns

- Fixed-direction skates for linear transportation

- Corner skate sets for balanced four-point support

- Hydraulic skates with integrated lifting capability

- Specialized configurations for particular load types

This diversity enables operations to select precisely the right skate configuration for their specific handling requirements, ensuring optimal functionality across different load types and transportation scenarios.

Applications Across Multiple Sectors

Equipment skates serve numerous sectors requiring controlled movement of substantial items, including:

- Manufacturing facilities repositioning production equipment

- Machinery installation contractors handling new equipment

- Building services companies installing HVAC systems

- Commercial moving operations transporting safes and cabinets

- IT infrastructure teams installing server equipment

- Facilities management relocating substantial furnishings

- Exhibition companies moving display equipment

- Industrial maintenance handling equipment during service

This versatility makes these specialized handling tools valuable additions to diverse operations where controlled movement of heavy items forms a regular component of operational activities or service delivery.

Enhanced Workplace Safety

A primary advantage of professional equipment skates is their significant contribution to workplace safety during challenging material handling operations. By providing proper engineered transportation solutions, these systems dramatically reduce common injury risks associated with improvised moving methods or manual handling attempts, including:

- Back injuries from excessive strain or improper techniques

- Crush injuries during unstable load movement

- Foot trauma from dropped items during handling

- Strain injuries from awkward positioning during manual efforts

- Hand and finger injuries during conventional movement attempts

This safety enhancement delivers both immediate operational benefits and long-term advantages through reduced workplace injuries, decreased lost-time incidents, and enhanced regulatory compliance. The professional design ensures loads remain controlled throughout transportation, eliminating unpredictable handling situations that commonly contribute to workplace accidents.

Facility Surface Protection

Beyond personnel safety, quality equipment skates provide valuable protection for facility flooring during heavy item transportation. Their specialized wheel compositions and load distribution characteristics prevent the surface damage, indentation, and marking commonly associated with moving substantial weights across finished flooring including concrete, tile, wood, and specialist industrial surfaces.

This protective functionality proves particularly valuable in premium environments where floor condition directly impacts facility appearance and where surface repairs represent significant maintenance expenses. The controlled weight distribution maintains floor integrity throughout transportation processes, preserving infrastructure investments while reducing maintenance requirements.

Precision Maneuverability for Exact Positioning

Despite handling substantial weights, professional-grade skates maintain excellent maneuverability characteristics essential for precise load positioning. Many systems incorporate advanced steering mechanisms, centre pivot designs, or swivel capabilities that enable exact final placement of heavy items according to installation requirements or operational specifications.

This positioning precision proves particularly valuable when installing sensitive equipment with specific alignment needs, placing machinery with critical foundation relationships, or positioning items in confined spaces with minimal clearance tolerances. The controlled movement enables confident handling with minimal repositioning requirements, enhancing efficiency while reducing handling risks.

Durable Professional Construction

Hall-Fast's equipment skates feature industrial-grade construction designed for reliable performance under substantial loads. Their frames incorporate high-strength materials selected for structural integrity despite intensive use, while roller systems utilize precision components engineered for extended service life under challenging operational conditions.

The load-bearing surfaces feature materials chosen for both durability and load capacity, maintaining functionality throughout extended operational lifespans despite regular deployment under maximum rated capacities. This emphasis on quality construction ensures these specialized tools deliver consistent performance despite the demanding applications typical in professional handling operations.

Space-Efficient Storage Between Deployments

Despite their substantial handling capability, quality equipment skates typically feature compact dimensions that facilitate practical storage between usage periods. Their space-efficient design enables convenient storage in service vehicles, maintenance facilities, or equipment storage areas without excessive space requirements.

This practical approach to equipment design ensures skates remain readily accessible when needed without imposing unreasonable storage demands during inactive periods. The efficient engineering creates specialized handling equipment that delivers exceptional capability without compromising operational practicality through excessive size or complex storage requirements.

Integration with Comprehensive Handling Systems

For complete material handling solutions, equipment skates can be implemented alongside additional tools from Hall-Fast's extensive range. Many operations deploy these specialized transportation systems alongside complementary handling equipment, creating integrated approaches to material movement that address diverse requirements through purpose-specific tool selection.

To explore additional handling options for comprehensive material management, visit Hall-Fast's complete handling and lifting collection at https://www.hall-fast.com/industrial-commercial-equipment/handling-lifting.

Hall-Fast supplies equipment skates from manufacturers recognized for innovation and quality in material handling solutions. For information about the brands available through Hall-Fast, visit their brands page at https://www.hall-fast.com/brands.

Expert Selection Guidance

Selecting optimal equipment skates requires consideration of multiple factors including typical load weights, surface conditions, movement distances, directional requirements, and specific handling priorities. Hall-Fast's experienced team provides expert guidance to help customers identify the most appropriate skate specifications for their specific material handling challenges.

For personalized assistance with selecting ideal equipment skates for your operations, contact Hall-Fast's specialists at https://www.hall-fast.com/contact. Their technical expertise ensures you'll receive informed recommendations tailored to your unique handling requirements and operational environment.

-

Adjustable Skates Pair 12000kg: Premium Heavy-Duty Transportation System for Industrial Applications

Starting at £442.09 £368.41

-

Starting at £589.96 £491.63

-

Starting at £338.59 £282.16

-

Starting at £481.27 £401.06

-

Starting at £486.46 £405.38

-

Starting at £185.76 £154.80

-

Heavy Duty Individual Skates with Swivel Castors: Versatile High-Capacity Material Handling Solution

Starting at £293.80 £244.83

-

Starting at £198.00 £165.00

-

Starting at £106.26 £88.55