Discover DEA WorkLab Series 110 at Hall-Fast - the versatile, standard-duty range of Italian-engineered industrial workspace solutions designed for general manufacturing, assembly, and technical operations. Our Series 110 collection delivers professional-grade construction, optimal capacity ratings, and proven DEA quality in standard dimensions suited for the majority of industrial applications, representing the perfect balance between functionality, capacity, and value.

What is DEA WorkLab Series 110?

DEA WorkLab Series 110 represents the standard-duty workhorse series in the DEA WorkLab family, engineered for typical industrial workspace requirements. Featuring 750mm depth profiles and load capacities of 400kg-600kg, Series 110 products deliver reliable performance for most manufacturing, assembly, quality control, and technical operations without the premium pricing of heavy-duty series or space constraints of compact models.

Series 110 Distinguishing Characteristics

Standard Depth Profile

Standard Depth: 750mm

Series 110 units feature 750mm depth providing:

- Adequate work envelope for most industrial tasks

- Proper storage depth for standard components and tools

- Comfortable operator positioning and reach zones

- Balance between functionality and floor space consumption

- Industry-standard dimensions for equipment integration

Comparison to Other Series:

- Series 90: 600mm (compact applications)

- Series 110: 750mm (standard applications)

- Series 150/200: 750mm-900mm (enhanced/heavy-duty)

Balanced Load Capacity

Working Load: 400kg-600kg (uniformly distributed)

Series 110 offers capacity suitable for:

- General assembly and manufacturing operations

- Standard tool and equipment loads

- Typical parts and material handling

- Quality inspection and testing

- Light to medium machining operations

Load Ratings:

- Workbench surfaces: 400kg-600kg

- Individual drawers: 50kg-75kg

- Cabinet shelves: 75kg-100kg

- Mobile units: 300kg-500kg

Versatile Width Range

Available Widths: 1200mm - 2100mm

Series 110 accommodates single to multi-operator configurations:

- 1200mm: Single-operator standard workstation

- 1500mm: Expanded single-operator or compact dual-access

- 1800mm: Dual-operator workstations

- 2100mm: Multi-operator or complex process stations

Standard Working Heights

Ergonomic Working Height: 850mm-900mmTotal Height (with upper structures): 1800mm-2200mm

Optimized dimensions supporting:

- Standing operator comfort

- Efficient material handling at work height

- Accessible upper storage and shelving

- Standard stool/chair accommodation for seated work

- Proper visual access and supervision

Comprehensive Storage Integration

Series 110 drawer units and cabinets feature:

- Drawer depths: 500mm-600mm

- Multiple height configurations (75mm-200mm)

- Full-extension slides for complete access

- Capacity for tools, parts, and equipment

- Organized storage for diverse applications

Series 110 Product Range

Series 110 Workbenches

Standard Single-Operator Workstations:

- Dimensions: 1200mm-1500mm width × 750mm depth

- Working height: 850mm-900mm

- Worktop thickness: 40mm-60mm depending on material

- Load capacity: 400kg-600kg

- Integrated lower shelf or drawer support

- Optional upper panel systems

Dual-Operator Workstations:

- Dimensions: 1800mm-2100mm width × 750mm depth

- Central divider or open-access configurations

- Individual tool panels per operator position

- Shared or dedicated storage modules

- Coordinated task lighting options

Applications:

- Assembly operations

- Manufacturing cells

- Quality control stations

- Equipment service and repair

- Testing and inspection

- Packaging and kitting

- General industrial work

Frame Construction:

- Welded steel tube: 50mm × 50mm profile

- Powder-coated RAL 7035 (grey) finish

- Reinforced corner construction

- Adjustable levelling feet (± 20mm)

- Optional caster kits for mobility

Series 110 Mobile Workstations

Standard Mobile Work Carts:

- Dimensions: 1200mm-1500mm width × 750mm depth

- Professional caster systems (125mm-150mm diameter)

- Work surface options: Beech, HPL, stainless steel

- Integrated storage shelves or drawer modules

- Load capacity: 300kg-500kg

Heavy-Duty Rolling Benches:

- Reinforced frame construction

- Thick worktop surfaces (50mm-60mm)

- Industrial-grade casters with braking

- Multiple shelf levels

- Tool panel integration

- Load capacity: 400kg-600kg

Mobility Features:

- Four swivel casters with brakes (standard)

- Push handle options

- Compact maneuverability

- Secure brake engagement

- Floor-protective wheels

Applications:

- Flexible manufacturing cells

- Point-of-use workstations

- Mobile tool stations

- Service and maintenance operations

- Material staging and kitting

Series 110 Drawer Units

Standard Drawer Cabinets:

- Width: 500mm-1000mm

- Depth: 750mm

- Height: 850mm-1350mm

- Drawer configurations: 4-9 drawers

- Individual drawer capacity: 50kg-75kg

- Total unit capacity: 300kg-500kg

Drawer Height Options:

- 75mm: Small components, fasteners

- 100mm: Hand tools, instruments

- 150mm: Larger tools, equipment

- 200mm: Bulky items, power tools

- Custom heights available

Features:

- Full-extension ball-bearing slides

- Individual drawer locks

- Anti-tilt mechanism (engages when drawer extended)

- Adjustable dividers and organizers

- Label holders for identification

- Smooth operation under full load

Under-Bench Drawer Units:

- Designed for workbench integration

- Matching 750mm depth

- Heights: 550mm-750mm (below work surface)

- Maximized workspace organization

- Accessible while working

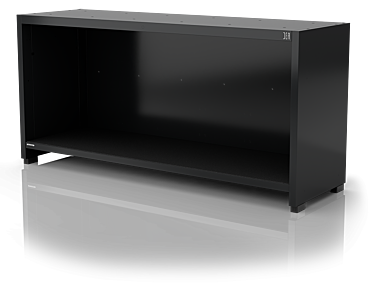

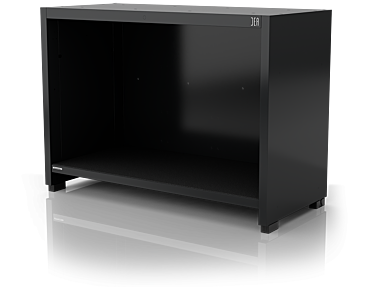

Series 110 Door Cabinets

Standard Storage Cabinets:

- Width: 500mm-1000mm

- Depth: 750mm

- Height: 1000mm-2000mm

- Single or double-door options

- 3-5 adjustable shelves (typical)

- Lockable security

Cabinet Configurations:

- Full-height cupboards (2000mm)

- Half-height units (1000mm-1200mm)

- Mixed door/drawer combinations

- Open shelving sections

- Perforated or solid door panels

Internal Features:

- Adjustable shelf spacing (50mm increments)

- Shelf load capacity: 75kg-100kg per shelf

- Optional drawer inserts

- Hook bars for hanging items

- Cable management provisions

Applications:

- Tool security and storage

- Parts inventory management

- Supply cabinets

- Equipment storage

- Document and manual storage

- PPE and safety equipment

Series 110 Wall Units

Overhead Storage Systems:

- Width: 1200mm-2100mm (matching bench widths)

- Depth: 300mm-450mm

- Height: 500mm-800mm

- Wall-mounted or bench-mounted

- Open shelving or glazed doors

Configurations:

- Open front with adjustable shelves

- Sliding glass doors

- Hinged glass or solid doors

- Combined open/closed sections

- Integrated lighting channels

Benefits:

- Vertical space utilization

- Frequently-used item storage

- Visual inventory management

- Dust and contamination protection

- Ergonomic access from standing position

Series 110 Panel Systems

Rear Panel Configurations:

- Perforated steel panels

- Widths matching workbench dimensions

- Height: 600mm-900mm above work surface

- Multiple accessory mounting options

Panel Accessories:

- Tool hooks and holders

- Bin rails and small parts containers

- Document holders and clipboards

- Power outlets and USB ports

- Task lighting integration

- Monitor arms and supports

Organization Benefits:

- Visual tool management (shadow boarding)

- Immediate tool accessibility

- Organized workflow support

- Flexible reconfiguration

- Reduced work surface clutter

Technical Specifications - Series 110

Frame Construction Standards

- Material: Welded steel tube, 50mm × 50mm rectangular profile

- Finish: Powder-coated epoxy, RAL 7035 (light grey) standard

- Welding: Full-penetration welds at structural joints

- Corner Reinforcement: Steel gusset plates for enhanced rigidity

- Levelling System: Adjustable feet with ± 20mm range

- Load Testing: 125% of rated capacity

Load Capacity Specifications

Workbenches:

- Uniformly distributed load: 400kg-600kg depending on worktop material

- Concentrated point load: 150kg-200kg

- Dynamic loads: Safety factor applied to rated capacity

- Load distribution: Evenly distributed across surface

Mobile Units:

- Static load: 300kg-500kg

- Dynamic (in motion): 250kg-400kg

- Includes weight of unit itself

- Load certification provided

Drawer Units:

- Per drawer: 50kg-75kg (varies by drawer height)

- Total cabinet: 300kg-500kg

- Anti-tip mechanism standard

- Load distribution across all drawers

Cabinet Shelving:

- Per shelf: 75kg-100kg

- Adjustable positioning

- Evenly distributed load requirement

Dimensional Standards

Workbench Dimensions:

- Width: 1200mm, 1500mm, 1800mm, 2100mm

- Depth: 750mm (standard)

- Working height: 850mm, 875mm, 900mm

- Total height with panel: 1800mm-2200mm

Mobile Workstation Dimensions:

- Width: 1200mm-1500mm (most common)

- Depth: 750mm

- Overall height: 900mm-1000mm (without upper structures)

- Caster diameter: 125mm-150mm

Storage Units:

- Width: 500mm, 600mm, 750mm, 1000mm

- Depth: 750mm (matching bench depth)

- Height: Variable (850mm-2000mm)

Worktop Material Options

Beech Hardwood:

- Thickness: 40mm (standard), 50mm, 60mm (heavy-duty)

- Surface: Oil-treated or varnished

- Edge detail: Square or rounded

- Load capacity contribution: 500kg-600kg

- Natural properties: Shock absorption, repairable

High-Pressure Laminate (HPL):

- Thickness: 30mm-40mm

- Core: Chipboard or MDF

- Surface: Melamine or phenolic laminate

- Chemical resistance: Good to excellent

- Load capacity contribution: 400kg-500kg

- Available Colors: Grey, beech effect, black

Stainless Steel:

- Gauge: 1.5mm-2.0mm over composite core

- Grade: 304 stainless steel (316 available)

- Total thickness: 30mm-40mm

- Surface finish: Brushed (#4 finish)

- Load capacity contribution: 500kg-600kg

- Hygiene: Cleanroom compatible

ESD-Safe Linoleum:

- Thickness: 30mm-40mm

- Surface resistance: 10⁶-10⁹ ohms (dissipative)

- Core: Conductive composite

- Grounding: Built-in provisions

- Load capacity contribution: 400kg-500kg

- Certification: ANSI/ESD S20.20 compliant

Key Applications for Series 110

General Manufacturing

Standard-duty workstations for:

- Product assembly operations

- Component fabrication

- Parts processing and finishing

- Inspection and quality control

- Packaging and preparation

- General machining support

Electronics & Precision Work

Suitable for:

- PCB assembly and testing

- Device manufacturing

- Component inspection

- Rework and repair stations

- Calibration and testing

- ESD-controlled environments (with appropriate worktops)

Automotive & Transportation

Supporting:

- Parts assembly and sub-assembly

- Component testing and inspection

- Tool preparation and staging

- Service and maintenance operations

- Quality verification stations

Medical Device & Pharmaceutical

Hygienic workspace for:

- Device assembly (with stainless tops)

- Component preparation

- Inspection and testing

- Packaging operations

- Laboratory support

Research & Development

Flexible workstations for:

- Prototype development

- Testing and evaluation

- Experimentation stations

- Laboratory work

- Engineering development

Maintenance & Repair Operations

Workshop stations supporting:

- Equipment service and repair

- Preventive maintenance

- Tool preparation

- Component refurbishment

- Diagnostic work

Education & Training

Cost-effective solutions for:

- Technical training facilities

- Educational workshops

- Skills development centres

- Apprenticeship programs

- Demonstration stations

Series 110 vs. Other DEA Series

When to Choose Series 110:

- Standard applications: Typical manufacturing and assembly work

- Balanced requirements: Good capacity without heavy-duty premium

- Versatile operations: Mix of tasks requiring flexible workspace

- Budget optimization: Professional quality at standard-duty pricing

- General industry: Broad range of applications across sectors

- Proven solutions: Established dimensions and configurations

When to Consider Series 90:

- Space-constrained environments (600mm depth)

- Compact footprint requirements

- Light-duty applications (300kg-400kg)

- Budget-conscious projects

- Mobile or temporary installations

When to Consider Series 150:

- Enhanced features and capacity (600kg-700kg)

- Specialized applications requiring specific configurations

- Premium finishes or advanced accessories

- Applications bridging standard and heavy-duty requirements

When to Consider Series 200:

- Heavy-duty applications (800kg+ capacity)

- Large work envelope requirements (900mm depth)

- Maximum storage integration

- Industrial-scale manufacturing operations

Benefits of Series 110

Proven Versatility

Series 110's standard dimensions and capacities address the broadest range of industrial applications, making it the default choice for general manufacturing, assembly, quality control, and technical operations across diverse industries.

Optimal Value Proposition

Balanced between compact and heavy-duty series, Series 110 delivers professional Italian quality, reliable capacity ratings, and comprehensive features at competitive pricing representing excellent value for standard-duty applications.

Wide Accessory Compatibility

As the core DEA series, Series 110 enjoys the broadest range of compatible accessories, organizational systems, and integration options, ensuring optimal customization and future expandability for evolving operational needs.

Established Reliability

With extensive field experience across industries worldwide, Series 110 represents proven, dependable workspace solutions with documented performance in demanding industrial environments and established maintenance procedures.

Flexible Configuration Options

Standard dimensions enable multiple configuration approaches - from standalone workstations to integrated production cells, mobile operations to fixed installations, supporting varied facility layouts and operational strategies.

Investment Security

Series 110's position as the standard DEA offering ensures long-term parts availability, accessory compatibility, and upgrade paths, protecting capital investments and supporting evolving operational requirements over extended service lives.

Modular Accessory Integration

Series 110 accommodates the complete DEA WorkLab accessory ecosystem:

Work Surface Accessories

- Bench Vises and clamping systems

- Articulating monitor arms

- Task lighting (LED and fluorescent)

- Power distribution strips

- Compressed air quick-connects

- Magnification systems

- Documentation holders

Storage & Organization

- Drawer divider systems

- Tool foam organization

- Bin rail systems with containers

- Hanging file provisions

- Small parts bins

- Tool shadow boards

- Security lock systems

Utility Integration

- Electrical distribution (single/three-phase)

- Pneumatic manifolds and regulators

- Vacuum system connections

- Fluid distribution provisions

- Cable management systems

- Grounding for ESD applications

Ergonomic Enhancements

- Anti-fatigue floor mats

- Adjustable height options (manual or electric)

- Footrests and positioning aids

- Seating integration (stools, chairs)

- Monitor positioning systems

Installation & Configuration

Site Requirements

- Level floor surface (± 3mm per meter)

- Adequate clearance for operation (minimum 900mm front access)

- Access for delivery and positioning

- Electrical/utility access if required

- Proper ventilation for confined spaces

Assembly & Installation

Pre-assembled Units:

- Mobile carts and small drawer units

- Ready for immediate use

- Minimal setup required

Modular Assembly:

- Larger workbenches and cabinet systems

- Frame assembly and component integration

- Panel and worktop installation

- Storage module mounting

Installation Time:

- Single workbench: 1-2 hours

- Complete workstation (bench + storage): 2-4 hours

- Multi-unit installations: Varies by scope

Professional Installation Services

Hall-Fast offers:

- Site survey and planning

- Professional assembly and installation

- Utility connection (where applicable)

- Testing and commissioning

- Operator training

- Documentation and certification

Maintenance & Longevity

Regular Maintenance Schedule

Daily:

- Clean work surfaces

- Inspect for damage

- Verify drawer operation

Weekly:

- Check fastener tightness

- Lubricate drawer slides (if needed)

- Verify levelling and stability

Monthly:

- Detailed inspection of components

- Adjustment of moving parts

- Check electrical/utility connections

- Clean drawer tracks and slides

Quarterly:

- Full system inspection

- Touch-up finish as needed

- Verify load-bearing components

- Update maintenance records

Annually:

- Comprehensive assessment

- Major cleaning and servicing

- Safety compliance verification

- Performance evaluation

Expected Service Life

With proper maintenance:

- Work surfaces: 10-15+ years

- Frame and structure: 20+ years

- Drawer slides: 10-15 years (depending on use)

- Casters: 5-10 years (depending on use)

- Finish: 10-15 years (with proper care)

Refurbishment Options

- Worktop replacement and upgrades

- Drawer slide replacement

- Finish restoration

- Caster replacement

- Accessory updates

- Configuration modifications

Integration with DEA WorkLab System

Series 110 integrates seamlessly across the DEA ecosystem:

- DEA Complete Units - Coordinated complete systems

- Industrial Workbenches - Compatible bench systems

- Industrial Worktops - Replacement surfaces

- Mobile Workstations - Mobility solutions

- Industrial Drawer Units - Storage integration

- Industrial Cabinets - Secure storage

- Industrial Door Cabinets - Cabinet solutions

- Fluid and Energy Distribution - Utility integration

- Series 90 - Compact applications

- Series 150 - Enhanced capacity

- Series 200 - Heavy-duty operations

Customization & Special Configurations

Standard Customizations

- Custom worktop dimensions within series parameters

- RAL Color matching for corporate branding

- Specialized worktop materials

- Custom drawer configurations

- Specific accessory packages

- Integrated equipment mounting

Engineered Solutions

- Multi-station integrated cells

- Process-specific configurations

- Clean room compliant units

- ESD-certified complete systems

- Hazardous location solutions

- Custom utility integration

Volume Projects

For facility-wide implementations:

- Comprehensive facility planning

- Coordinated design across departments

- Standardized configurations for efficiency

- Phased delivery and installation

- Training and documentation

- Long-term support agreements

Safety & Compliance

European Standards

- EN 1757-1: Storage furniture safety

- EN ISO 12100: Machinery safety (general)

- Load capacity testing per EN standards

- Stability testing and certification

- Electrical safety (where applicable): CE marked components

Workplace Safety

- Anti-tip mechanisms on drawer units

- Rounded edges and corners

- Secure mounting provisions

- Load capacity labelling

- Safe operation instructions

- Proper warning labels

Ergonomic Standards

- Working height per EN 1729 guidance

- Reach zone optimization

- Visual access considerations

- Proper clearance dimensions

- Operator comfort prioritization

Why Choose Hall-Fast for Series 110?

- Authorized DEA Supplier - Genuine Italian-manufactured Series 110 products

- Comprehensive Stock - Full range of configurations readily available

- Expert Consultation - Professional guidance on optimal configurations

- Custom Solutions - Bespoke adaptations for unique requirements

- Competitive Pricing - Best value on quality standard-duty systems

- Fast Turnaround - Quick delivery on stock and custom units

- Quality Assurance - Thorough inspection and testing

- Installation Support - Professional installation services available

- Technical Expertise - Deep knowledge of DEA WorkLab systems

- Long-term Partnership - Ongoing support and service

Get Series 110 Standard Workspace Solutions

Transform your operations with proven DEA WorkLab Series 110 standard-duty workspace systems from Hall-Fast. Contact our industrial workspace specialists for expert guidance on optimal Series 110 configurations, custom solutions, and complete systems perfectly matched to your operational requirements and quality standards.

Contact Hall-Fast:

- Phone: 01623 645645

- Email:sales@hall-fast.com

Request detailed specifications, configuration recommendations, custom quotations, or place your order today. Hall-Fast - your trusted supplier of standard Italian industrial workspace solutions throughout the UK.

-

£2,824.62 £2,353.85

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price