Introduction: Why Proper Drum Storage Matters

In industrial environments where drums containing chemicals, oils, lubricants, or other materials are used daily, the challenge of safe, efficient storage and handling is paramount. Improper drum storage leads to workplace injuries, regulatory non-compliance, product contamination, and operational inefficiencies that cost businesses thousands annually. This is where specialized equipment like Stubbs® Drum Cradle Stands becomes not just helpful, but essential.

This comprehensive guide explores everything you need to know about Stubbs® Drum Cradle Stands – from their engineering and applications to selection criteria and maintenance best practices. Whether you're a facilities manager, health and safety officer, warehouse supervisor, or procurement specialist, this article will equip you with the knowledge to make informed decisions about drum storage infrastructure.

What Are Stubbs® Drum Cradle Stands?

Defining Drum Cradle Technology

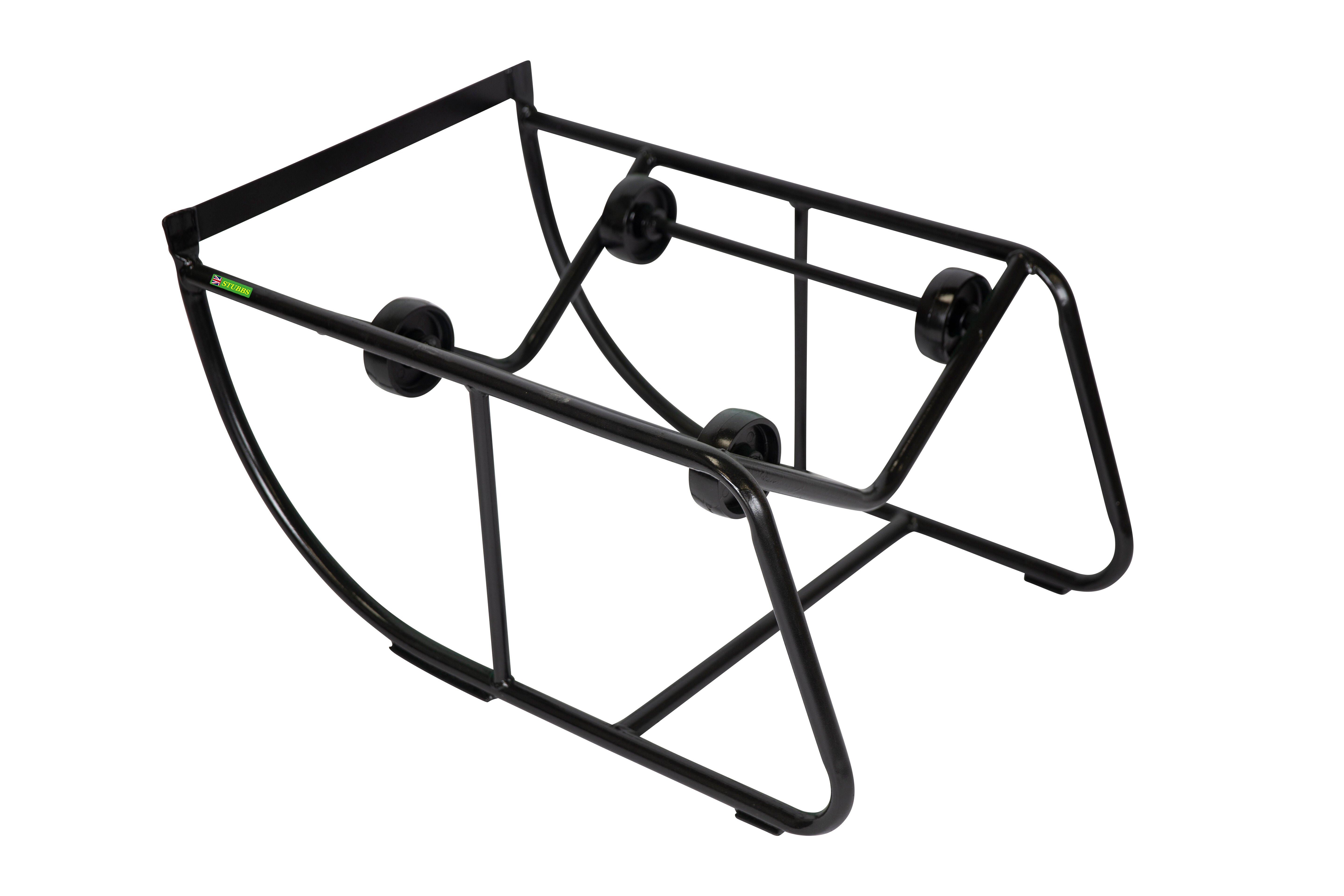

Stubbs® Drum Cradle Stands are engineered industrial storage systems specifically designed to hold 210-litre (45-gallon) steel drums and compatible plastic drums in a secure, horizontal position. Unlike vertical drum storage where drums stand upright, cradle stands position drums on their side, enabling easier access to drum contents through the bung openings while maintaining stability and preventing rolling.

The cradle design features a curved or formed support structure that conforms to the cylindrical shape of standard industrial drums. This design distributes the drum's weight evenly across the support points, eliminating pressure concentration that could damage drums or cause instability. The stands elevate drums off the ground, improving ergonomics, facilitating drainage, and protecting drum bottoms from moisture and corrosion.

The Stubbs® Heritage of Quality

Stubbs has been manufacturing industrial and agricultural equipment since 1836, representing nearly two centuries of British engineering excellence. Originally established to serve the equestrian industry, Stubbs expanded into industrial applications, bringing the same commitment to quality, durability, and practical design that made their stable equipment legendary. When you invest in Stubbs® Drum Cradle Stands, you're purchasing equipment built on generations of manufacturing expertise and a reputation for products that withstand decades of demanding use.

Engineering Specifications and Construction

Stubbs® Drum Cradle Stands feature heavy-duty steel construction with industrial-grade corrosion-resistant finishes. The stands are engineered to support the substantial weight of filled 210L drums, which can exceed 200kg depending on contents. The cradle design incorporates:

- Formed Steel Cradle: Precisely shaped to match standard drum dimensions, providing secure support along the drum's length

- Reinforced Base Structure: Wide stance design ensures stability under load

- Industrial Coating: Powder-coated or galvanized finish protects against chemicals, moisture, and environmental degradation

- Drainage Consideration: Design allows for controlled tipping and drainage when required

- Load Distribution: Engineering ensures weight is properly distributed to prevent deformation

Key Features and Benefits of Stubbs® Drum Cradle Stands

Enhanced Workplace Safety

Injury Prevention: Manual handling of drums is one of the leading causes of workplace injuries in industrial settings. A filled 210L drum weighs 200kg or more, making it impossible to lift safely without mechanical assistance. Stubbs® Drum Cradle Stands eliminate much of this risk by:

- Providing stable storage that prevents drums from rolling or tipping

- Elevating drums to ergonomic heights for easier access

- Reducing the need to manually reposition heavy drums

- Preventing back strain, crush injuries, and repetitive strain conditions

Spill Prevention: Drums stored improperly can tip, leak, or be accidentally knocked over, causing hazardous spills. The secure cradle design prevents accidental movement and provides controlled positioning for dispensing operations, significantly reducing spill risk and the associated cleanup costs, environmental impact, and regulatory consequences.

Compliance Support: Health and Safety Executive (HSE) regulations require employers to minimize manual handling risks. Implementing proper drum storage equipment demonstrates due diligence and helps organizations meet their legal obligations under the Manual Handling Operations Regulations 1992 and the Management of Health and Safety at Work Regulations 1999.

Operational Efficiency Improvements

Faster Drum Access: When drums are stored in cradles at working height with bung openings readily accessible, workers can quickly connect dispensing equipment, drain contents, or transfer materials without time-consuming repositioning. This translates directly to productivity gains, especially in operations involving multiple drum changes daily.

Simplified Inventory Management: Organized drum storage on dedicated stands makes inventory tracking straightforward. Drums are clearly visible, easily labeled, and simple to count during stock checks. This reduces the risk of expired materials going unnoticed and improves just-in-time material management.

Space Optimization: While drums take up floor space regardless of storage method, cradle stands enable more organized layouts with defined storage zones. This prevents the chaotic accumulation of drums and creates clear pathways for material flow and personnel movement.

Reduced Product Contamination: Elevating drums off the floor protects them from ground moisture, dirt, and debris. This is particularly important in food-grade, pharmaceutical, or clean manufacturing environments where contamination could compromise product quality.

Economic Advantages

Long-Term Durability: Stubbs® equipment is engineered for decades of service. While the initial investment may exceed cheaper alternatives, the total cost of ownership is significantly lower when you factor in replacement costs, repair frequency, and downtime from equipment failures.

Drum Protection: By providing proper support and preventing damage to drum surfaces and rolling hoops, cradle stands extend drum lifespan. This is especially valuable with returnable drums where damage fees can accumulate quickly.

Insurance and Liability: Proper drum storage reduces the likelihood of accidents, spills, and injuries that could result in insurance claims, regulatory fines, or litigation. Many insurers look favorably on proper material handling infrastructure when assessing risk and setting premiums.

Applications Across Industries

Chemical Processing and Storage Facilities

Chemical plants and storage facilities handle numerous drum types containing everything from solvents and acids to specialty chemicals and intermediates. Stubbs® Drum Cradle Stands provide:

- Chemical Resistance: Industrial coatings resist degradation from chemical exposure

- Segregation Support: Organize incompatible materials safely with dedicated storage zones

- Dispensing Integration: Easy connection of pumps, hoses, and transfer equipment

- Spill Containment Compatibility: Stands can be positioned within secondary containment pallets

Manufacturing Operations

Manufacturing facilities use drums for oils, lubricants, coolants, cleaning solutions, and raw materials. In these environments, drum cradle stands enable:

- Point-of-Use Storage: Position drums near machinery for convenient access

- Waste Management: Organize waste oil, coolant, and solvent collection drums

- Quality Control: Proper storage prevents contamination of production materials

- Lean Manufacturing: Support just-in-time material delivery with organized storage

Automotive Workshops and Service Centers

Auto repair facilities accumulate used oils, antifreeze, solvents, and other automotive fluids in drums. Drum cradle stands facilitate:

- Waste Stream Separation: Organize different waste types for proper disposal

- Dispensing Operations: Easy access for filling waste oil from drain pans

- Compliance: Meet environmental regulations for fluid storage and handling

- Shop Organization: Professional appearance with organized drum storage

Pharmaceutical and Food Production

In regulated industries where cleanliness and documentation are critical, drum cradle stands offer:

- Sanitary Design: Elevated storage prevents floor contamination

- Batch Traceability: Organized storage supports lot tracking requirements

- GMP Compliance: Proper material handling supports Good Manufacturing Practice

- Cleanroom Compatible: Stainless steel or special finish options for controlled environments

Paint and Coatings Industry

Paint manufacturers, contractors, and industrial coating operations benefit from:

- Color Organization: Separate storage for different products prevents cross-contamination

- Dispensing Convenience: Horizontal storage facilitates pumping operations

- Viscous Material Handling: Gravity-assisted drainage for thick materials

- Spray Booth Supply: Organized drum storage near application areas

Agricultural and Horticultural Operations

Farms and nurseries handling fertilizers, pesticides, and other agricultural chemicals need:

- Weather Resistance: Durable construction withstands outdoor storage conditions

- Pesticide Safety: Secure storage prevents accidental exposure or spills

- Seasonal Storage: Organize products by application season

- Regulatory Compliance: Meet agricultural chemical storage requirements

Understanding Drum Storage Standards and Regulations

UK Health and Safety Requirements

The Health and Safety Executive (HSE) provides comprehensive guidance on drum storage and handling through various regulations and approved codes of practice:

Manual Handling Operations Regulations 1992: These regulations require employers to avoid hazardous manual handling operations where possible, assess unavoidable risks, and reduce risks through proper equipment provision. Drum cradle stands directly address these requirements by eliminating unsafe manual drum manipulation.

Control of Substances Hazardous to Health Regulations 2002 (COSHH): COSHH requires proper storage of hazardous materials, including consideration of stability, spill prevention, and access control. Drum cradle stands support COSHH compliance through secure storage and organized material management.

Workplace (Health, Safety and Welfare) Regulations 1992: These regulations address general workplace organization, cleanliness, and safe working conditions. Proper drum storage equipment contributes to overall workplace safety and organization standards.

Environmental Regulations

Environmental Protection Act 1990 and Environmental Permitting Regulations 2016 establish requirements for preventing environmental pollution from stored materials. Key considerations include:

- Secondary Containment: Drum storage may require spill containment systems

- Storage Location: Requirements for distance from drains, watercourses, and boundaries

- Labeling: Clear identification of stored substances

- Inspection: Regular checks for leaks or deterioration

Drum cradle stands should be used in conjunction with appropriate spill containment pallets or bunded areas when storing polluting substances.

Industry-Specific Standards

Different sectors may have additional requirements:

Pharmaceutical: Good Manufacturing Practice (GMP) guidelines specify material storage requirements including cleanliness, organization, and traceability.

Food Industry: Food Safety Modernization Act (FSMA) and BRC Global Standards require proper storage of food-grade materials and prevention of contamination.

Chemical Industry: COMAH (Control of Major Accident Hazards) Regulations may apply to facilities storing large quantities of hazardous substances.

Selecting the Right Drum Cradle Stand Configuration

Drum Compatibility Considerations

While Stubbs® Drum Cradle Stands are designed for standard 210L (45-gallon) drums, variations exist:

Steel Drums: Most common in industrial applications, steel drums have reinforced rolling hoops and are available in closed-head (sealed) and open-head (removable lid) configurations. Cradle stands must accommodate the rolling hoop dimensions.

Plastic Drums: HDPE (high-density polyethylene) plastic drums with L-ring or X-ring closures have different exterior profiles. Ensure compatibility with plastic drum dimensions if this is your application.

Fiber Drums: Less common in industrial settings, fiber drums may require different support characteristics due to their construction.

Specialty Drums: Some industries use stainless steel drums, UN-rated drums, or other specialized containers. Verify compatibility before ordering.

Load Capacity Requirements

Calculate the maximum weight your stands must support:

- Water: 210L = 210kg

- Oil/Petroleum Products: 170-180kg typically

- Chemicals: Variable density; some exceed water weight

- Safety Factor: Select equipment rated well above maximum expected load

Mobility Considerations

Stationary Stands: Basic drum cradle stands provide fixed storage locations ideal for:

- Permanent drum storage areas

- Point-of-use stations with consistent material supply

- Maximum stability when mobility isn't required

Mobile Drum Cradles: Some drum cradles incorporate wheels and castors for mobility. These are valuable when:

- Drums need regular repositioning

- Space is limited and equipment must be moved for cleaning

- Drums serve multiple work areas

- Flexibility is more important than maximum stability

Hall-Fast offers mobile drum cradle options with heavy-duty castors and wheel systems for applications requiring movement.

Quantity and Layout Planning

Determine how many drum cradle stands you need based on:

Maximum On-Site Inventory: Count peak drum quantities across all product types Segregation Requirements: Incompatible materials need separate storage zones Operational Flow: Position stands to support efficient material movement Future Growth: Consider expansion when planning storage infrastructure Access Requirements: Ensure adequate spacing for forklift access, inspection, and emergency response

Installation and Setup Best Practices

Site Preparation

Floor Requirements: Drum cradle stands should be positioned on:

- Level, solid flooring capable of supporting concentrated loads

- Non-combustible surfaces for flammable material storage

- Impervious flooring or secondary containment for hazardous materials

- Well-drained areas to prevent water accumulation

Environmental Factors: Consider:

- Temperature Control: Some materials require climate-controlled storage

- Ventilation: Adequate airflow prevents vapor accumulation

- Lighting: Proper illumination for safe operations and inspections

- Weather Protection: Indoor storage preferred; outdoor storage requires covered areas

Access and Clearances: Plan for:

- Minimum 1-meter clearances around drum stands for inspection and emergency access

- Forklift aisle widths if drums will be moved mechanically

- Distance from ignition sources for flammable materials

- Proximity to emergency equipment (eyewash stations, fire extinguishers, spill kits)

Assembly and Installation

Most drum cradle stands arrive ready to use or require minimal assembly:

- Inspect on Delivery: Check for shipping damage and verify all components are included

- Position Correctly: Place stands according to your layout plan, ensuring level placement

- Secure if Required: Some applications may benefit from anchoring stands to floors

- Install Secondary Containment: Position spill pallets or bunding as required

- Label Storage Areas: Clearly mark what materials are stored in each location

Integration with Existing Systems

Dispensing Equipment: Plan how pumps, hoses, and transfer equipment will connect to drums in cradle stands. Consider:

- Pump mounting options (drum-mounted vs. external)

- Hose routing and storage

- Drip containment during connections

Inventory Management: Integrate drum storage with your inventory system:

- Install signage or label holders on stands

- Implement barcode or RFID tracking if applicable

- Establish protocols for recording drum receipt, usage, and disposal

Safety Systems: Ensure drum storage integrates with overall facility safety:

- Fire suppression system coverage

- Spill response equipment proximity

- Emergency lighting and exit access

- Ventilation system adequacy

Maintenance and Inspection Protocols

Routine Maintenance Tasks

Weekly Inspections:

- Visual check for obvious damage or deterioration

- Verify drums remain properly positioned in cradles

- Look for new spills or leaks

- Ensure labeling remains legible and accurate

Monthly Maintenance:

- Inspect structural integrity of stands (welds, connections, base)

- Check for corrosion, especially in chemical storage areas

- Clean stands to remove accumulated dust, spills, or residues

- Verify secondary containment systems remain intact

- Test mobility features if applicable (wheels, castors)

Annual Reviews:

- Comprehensive structural assessment

- Load test if stands show wear or damage

- Evaluate coating condition; plan for refinishing if deteriorating

- Review storage layout for optimization opportunities

- Update risk assessments and safe operating procedures

Cleaning Procedures

Proper cleaning extends equipment life and maintains safe conditions:

- Remove Drums: Empty the cradle stand before cleaning

- Remove Loose Debris: Sweep or vacuum dust and particulates

- Apply Cleaning Solution: Use appropriate detergents for contamination type

- Scrub if Needed: Remove stubborn residues with brushes

- Rinse Thoroughly: Prevent cleaner accumulation

- Dry Completely: Use compressed air or allow air drying before replacing drums

- Inspect During Cleaning: Look for damage that might not be visible when loaded

Documentation and Record Keeping

Maintain records of:

- Initial installation dates and configurations

- Inspection schedules and findings

- Maintenance activities and repairs

- Any incidents involving drum storage equipment

- Equipment modifications or upgrades

This documentation demonstrates due diligence for regulatory compliance and helps identify patterns that might indicate problems requiring attention.

Cost Considerations and Return on Investment

Initial Investment Analysis

Stubbs® Drum Cradle Stands represent a premium equipment choice with pricing reflecting their quality construction and longevity. When evaluating costs, consider:

Direct Purchase Costs:

- Equipment price per stand

- Delivery charges

- Installation materials (if professional installation required)

- Associated equipment (spill pallets, pumps, accessories)

Total Cost Comparison: Compare not just initial price but:

- Expected lifespan (Stubbs® equipment often lasts 20+ years vs. 5-10 for economy options)

- Maintenance requirements and costs

- Warranty coverage and terms

- Replacement part availability

Quantifying ROI Benefits

Injury Cost Avoidance: Back injuries from manual handling average £8,000-£30,000 in direct costs (medical, lost time, replacement labor) with potential for much higher costs if permanent disability results. Preventing even one serious injury can justify significant equipment investment.

Operational Efficiency Gains: If proper drum storage saves each worker 10 minutes per day in a facility with 10 workers handling drums:

- 10 workers × 10 minutes × 250 workdays = 25,000 minutes = 417 hours annually

- At £15/hour labor cost = £6,250 annual savings

- Over 20-year equipment life = £125,000 total savings

Reduced Product Loss: Spill prevention saves material costs, cleanup expenses, environmental penalties, and business interruption. A single significant spill can cost thousands to tens of thousands in direct expenses.

Insurance Benefits: Some insurers offer premium reductions for documented safety improvements. Even a 2-3% reduction on liability insurance can represent substantial savings for larger operations.

Financing and Procurement Options

Hall-Fast offers various procurement approaches:

- Direct purchase for immediate ownership

- Volume discounts for large orders

- Flexible payment terms for established accounts

- Integration with capital equipment budgeting cycles

Proper drum storage equipment often qualifies for health and safety improvement budgets, environmental compliance funding, or capital equipment allocations.

Comparing Drum Storage Alternatives

Vertical Drum Storage

Advantages:

- Slightly smaller footprint per drum

- Simple storage approach

- Lower equipment costs (pallets vs. cradle stands)

Disadvantages:

- Difficult access to bung openings

- Requires drum tilting for dispensing (injury risk)

- Contents settle at bottom (harder to fully empty)

- Height makes inspection of drum tops difficult

Drum Racks and Stacking Systems

Advantages:

- Vertical space utilization

- High-density storage possible

- Good for long-term storage of sealed drums

Disadvantages:

- Not suitable for active dispensing operations

- Requires forklift for drum access

- Higher fall risk if improperly loaded

- Difficult inspection of upper-level drums

Floor Storage Without Stands

Advantages:

- Zero equipment cost

- Ultimate flexibility in drum positioning

Disadvantages:

- Drums can roll creating serious hazards

- Ground contact promotes corrosion

- Very poor ergonomics

- Appears unprofessional and disorganized

- High injury risk

- Difficult to implement spill containment

- Regulatory compliance challenges

Conclusion: While alternatives exist, horizontal drum cradle stands offer the best combination of safety, accessibility, and operational efficiency for active drum usage environments.

Frequently Asked Questions

Q: What drum sizes are compatible with Stubbs® Drum Cradle Stands? A: The standard configuration accommodates 210L (45-gallon) steel drums, the most common industrial drum size. Compatibility with plastic drums depends on their exterior profile; verify specifications before ordering.

Q: Can drum cradle stands be used outdoors? A: While Stubbs® stands feature corrosion-resistant finishes suitable for outdoor use, best practice recommends covered storage to protect both equipment and drum contents from weather exposure. If outdoor storage is necessary, implement additional protective measures.

Q: Do I need spill containment pallets with drum cradle stands? A: Regulatory requirements for secondary containment depend on what substances you're storing and local environmental regulations. For petroleum products, chemicals, or any potential pollutants, secondary containment is typically required. Cradle stands can be positioned within or on top of spill pallets.

Q: How many drums can I store per square meter? A: This depends on stand dimensions, required clearances, and access needs. Typically, allow approximately 1.5-2 square meters per drum when accounting for the stand footprint, inspection access, and operational space.

Q: Can drum cradle stands support drums while dispensing? A: Yes, this is a primary use case. The stable support allows safe connection of pumps and dispensing equipment. Ensure the total weight (drum + dispensing equipment) remains within the stand's load capacity.

Q: How do I clean cradle stands that have chemical residues? A: Follow your facility's chemical handling procedures. Generally: wear appropriate PPE, remove the drum, neutralize or absorb residues as appropriate for the specific chemical, clean with compatible solvents or detergents, rinse thoroughly, and properly dispose of cleaning materials.

Q: What's the expected lifespan of Stubbs® Drum Cradle Stands? A: With proper maintenance, Stubbs® equipment typically provides 20+ years of service. The heavy-duty construction and corrosion-resistant finishes ensure longevity even in demanding environments.

Q: Can stands be customized for specific applications? A: While Stubbs® offers standard configurations optimized for common applications, custom solutions may be available for specialized requirements. Contact Hall-Fast to discuss specific needs.

Ordering Stubbs® Drum Cradle Stands from Hall-Fast

Why Choose Hall-Fast as Your Supplier

Hall-Fast has supplied industrial and commercial equipment for over two decades, building a reputation for:

Product Expertise: Their team understands material handling challenges across various industries and can recommend optimal solutions for your specific requirements.

Comprehensive Range: Beyond drum cradle stands, Hall-Fast offers complete drum handling systems including mobile cradles, forklift attachments, drum tilters, lifters, and accessories—enabling you to source complete solutions from one supplier.

Quality Assurance: Hall-Fast partners with established manufacturers like Stubbs® known for quality and reliability, ensuring you receive equipment that meets rigorous standards.

Competitive Pricing: Volume purchasing power and efficient operations enable Hall-Fast to offer competitive pricing without compromising quality.

Customer Service: From initial inquiry through post-purchase support, Hall-Fast's team provides responsive, knowledgeable service.

Fast Delivery: Many items ship same-day or next-day for stock products, minimizing downtime when equipment is needed urgently.

How to Order

1. Assess Your Requirements: Determine:

- Number of drum cradle stands needed

- Drum types and sizes you'll store

- Environmental conditions (indoor/outdoor, chemical exposure)

- Mobility requirements (stationary vs. mobile)

- Associated equipment needs (spill pallets, pumps, etc.)

2. Contact Hall-Fast: Reach out through:

- Phone: 01623 645645 for immediate assistance

- Email: sales@hall-fast.com for detailed inquiries

- Website: www.hall-fast.com to browse products and specifications

3. Consult with Experts: Hall-Fast's team will:

- Clarify your application requirements

- Recommend appropriate products

- Provide detailed specifications

- Quote competitive pricing

- Explain delivery timelines

4. Place Your Order: Once you've selected equipment:

- Receive formal quotation

- Review and approve

- Submit purchase order or payment

- Confirm delivery details

5. Receive and Install: Upon delivery:

- Inspect shipment for damage

- Verify against order

- Install per guidelines

- Begin operations with improved safety and efficiency

After-Sales Support

Hall-Fast's commitment extends beyond the sale:

- Technical support for installation questions

- Maintenance guidance

- Replacement part sourcing if needed

- Product recommendations for related equipment

- Ongoing consultation as your needs evolve

Conclusion: Investing in Safe, Efficient Drum Storage

Proper drum storage infrastructure represents a fundamental investment in workplace safety, operational efficiency, and regulatory compliance. Stubbs® Drum Cradle Stands deliver the quality, durability, and practical design that professional operations demand.

By eliminating unsafe manual handling, organizing material storage, preventing spills, and supporting efficient workflows, drum cradle stands pay for themselves many times over through injury prevention, productivity improvements, and reduced material losses.

Whether you're outfitting a new facility, upgrading aging equipment, or addressing safety concerns identified in risk assessments, Stubbs® Drum Cradle Stands from Hall-Fast provide a proven solution backed by nearly two centuries of manufacturing excellence.

Take Action Today: Don't let another day pass with inadequate drum storage putting your workers at risk and limiting operational efficiency. Contact Hall-Fast now to discuss how Stubbs® Drum Cradle Stands can transform your material handling operations.

Hall-Fast Industrial Supplies Phone: 01623 645645 Email: sales@hall-fast.com Website: www.hall-fast.com

Free delivery on orders over £54.99 | Expert advice available | Next-day delivery on stock items

This comprehensive guide provides general information about drum cradle stands and safe drum handling practices. Specific regulatory requirements vary by location, industry, and materials handled. Consult with qualified health and safety professionals and regulatory authorities to ensure your drum storage solutions meet all applicable requirements for your specific situation.