In environments where electrostatic discharge (ESD) poses a significant threat, every aspect of storage and material handling requires specialized protection. The Eclipse® Chrome Wire ESD Shelving system represents the gold standard in ESD-safe storage solutions, providing critical protection for sensitive electronic components while offering exceptional versatility and durability. This comprehensive guide explores how these specialized shelving systems from award-winning global supplier Hall-Fast are revolutionizing ESD protection in industries worldwide.

Understanding Electrostatic Discharge Risks in Storage Environments

Electrostatic discharge presents one of the most insidious threats to electronic components, capable of causing both catastrophic failures and latent damage that manifests only after products reach end-users. While much attention focuses on workstation protection, storage areas present equally significant risks, with charges potentially building on conventional shelving systems and discharging into sensitive components.

Storage-related ESD events typically occur through three primary mechanisms:

- Direct Discharge to Components: When charged personnel handle components stored on non-ESD shelving

- Charge Transfer from Shelving: When conventional shelves develop static charges that transfer to stored items

- Induced Charging: When charged objects near conventional shelving induce charges on stored components

The financial impact of these events extends beyond immediate component damage to include:

- Reduced manufacturing yields

- Reliability issues in finished products

- Increased warranty claims

- Customer dissatisfaction

- Reputation damage

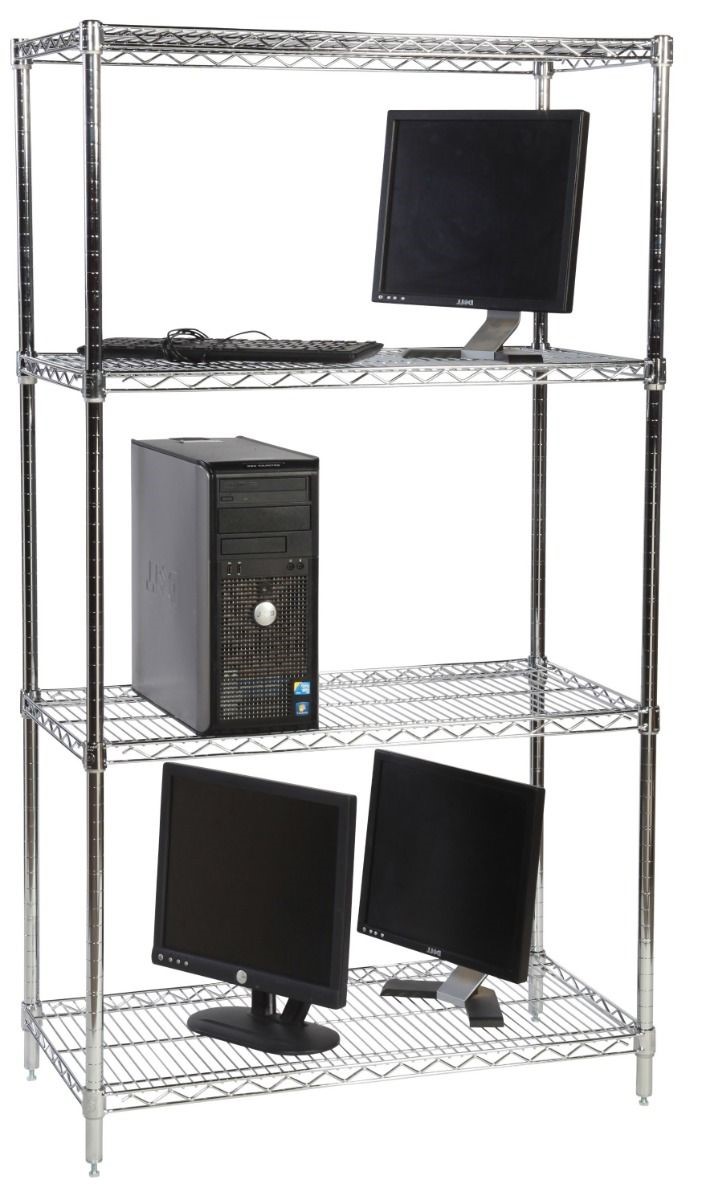

Eclipse® Chrome Wire ESD Shelving: Superior Design and Engineering

The Eclipse® Chrome Wire ESD Shelving system available through Hall-Fast represents the culmination of advanced engineering specifically addressing the unique requirements of ESD-sensitive storage environments. These shelving systems incorporate several critical design elements:

- Advanced Conductive Chrome Coating

The proprietary chrome plating process used in Eclipse® ESD shelving creates a consistent conductive surface that:

- Maintains surface resistivity between 1×10^4 and 1×10^6 ohms

- Provides continuous conductive pathways for charge dissipation

- Ensures constant electrical continuity throughout the entire shelving structure

- Resists corrosion and wear that could compromise ESD protection

This specialized chrome finish significantly outperforms conventional chrome plating or painted surfaces, providing reliable ESD protection throughout the product's extended service life.

- Robust Wire Construction

The wire mesh design of Eclipse® ESD shelving offers several advantages in ESD-sensitive environments:

- Minimized Surface Area: Reduces potential for dust accumulation and static buildup

- Superior Air Circulation: Prevents static-promoting hot spots and maintains temperature consistency

- Enhanced Visibility: Allows visual inspection of stored components without handling

- Weight Reduction: Facilitates reconfiguration without compromising structural integrity

- Cleaning Efficiency: Permits thorough cleaning without disassembly

Each shelf is capable of supporting substantial loads while maintaining full ESD protection, with weight capacities ranging from 250kg to 350kg depending on specific configuration.

- Comprehensive Grounding System

Eclipse® Chrome Wire ESD Shelving incorporates a complete grounding infrastructure that ensures reliable charge dissipation:

- Integrated Grounding Points: Specially designed connection points at multiple locations

- Continuous Conductivity: Assured electrical continuity between all shelving components

- Compatible Grounding Hardware: Standardized connections for facility-wide ESD systems

- Visual Verification: Clear indicators confirming proper grounding connections

- Testing Access Points: Designated locations for regular resistance verification

This systematic approach to grounding ensures that static charges are consistently and reliably channelled to ground rather than to sensitive components.

- Modular Configuration Options

The Eclipse® ESD shelving system offers exceptional versatility to accommodate diverse storage requirements:

- Multiple Depth Options: Available in 455mm, 610mm, and custom depths

- Adjustable Heights: Shelf positions adjustable in 25mm increments

- Starter and Add-on Units: Expandable configuration options

- Mobile Variants: Available with ESD-compliant castors for dynamic storage needs

- Compatible Accessories: Including dividers, ledges, and label holders

This flexibility allows organizations to create customized storage solutions precisely tailored to their specific component protection requirements.

Industry-Specific Applications for Eclipse® Chrome Wire ESD Shelving

Electronics Manufacturing

Electronics manufacturers utilize Eclipse® ESD shelving for:

- Component Staging Areas: Safely storing PCB components before assembly

- Work-in-Progress Storage: Maintaining ESD protection between production steps

- Finished Goods Inventory: Protecting completed assemblies awaiting shipment

- Tool and Equipment Storage: Safeguarding ESD-sensitive testing and assembly equipment

- Documentation Organization: Keeping production documentation away from static-generating materials

Leading electronics manufacturers worldwide source their Eclipse® ESD shelving through Hall-Fast to maintain continuous ESD protection throughout their production environments.

Semiconductor Fabrication

The semiconductor industry's exacting standards for cleanliness and static control make Eclipse® Chrome Wire ESD Shelving an ideal solution for:

- Wafer Storage: Providing static-free storage for silicon wafers between process steps

- Clean Room Material Management: Organizing supplies without compromising cleanliness

- Sensitive Equipment Storage: Housing specialized testing and measurement devices

- Consumables Organization: Maintaining order in high-value component inventory

The open wire design minimizes particulate accumulation critical in semiconductor environments while providing necessary ESD protection.

Medical Device Manufacturing

Medical device manufacturers producing implantable and diagnostic electronic devices utilize Eclipse® ESD shelving for:

- Component Quarantine Areas: Segregating incoming materials awaiting inspection

- Controlled Environment Storage: Maintaining both ESD protection and cleanliness standards

- Calibrated Tool Organization: Housing sensitive calibration and testing equipment

- Validated Process Material Storage: Ensuring components remain protected within validated processes

The robust construction and reliable ESD protection provide the performance necessary in these heavily regulated environments.

Aerospace and Defence Applications

The aerospace and defence sectors implement Eclipse® ESD shelving for:

- Avionics Component Storage: Protecting sophisticated electronic navigation and control systems

- Satellite Subsystem Organization: Housing sensitive communication and imaging components

- Military Electronics Inventory: Safeguarding critical defence electronic systems

- Research and Development Materials: Organizing prototype components and test assemblies

The exceptional durability and reliable ESD protection make these shelving systems ideal for mission-critical applications.

Implementing Eclipse® ESD Shelving in Your Facility

Comprehensive ESD Protected Area Design

Integrating Eclipse® Chrome Wire ESD Shelving into a complete ESD Protected Area (EPA) requires thoughtful planning:

- Systematic Layout Assessment: Analysing workflow and material movement to optimize shelving placement

- Grounding Infrastructure Integration: Ensuring shelving systems connect properly to facility-wide grounding grid

- Complementary Solutions Implementation: Coordinating with other ESD protection measures including:

- Eclipse® Chrome ESD Workbenches for processing areas

- Appropriate flooring and footwear systems

- Environmental monitoring equipment

- Personnel grounding equipment

- Documentation and Training: Establishing proper protocols for shelving usage and maintenance

Hall-Fast consultants can provide expert guidance on integrating Eclipse® ESD shelving into comprehensive facility protection plans.

Testing and Verification Protocols

Maintaining effective ESD protection requires regular verification of Eclipse® shelving performance:

- Surface Resistivity Testing: Regular measurement of shelf surface resistivity

- Ground Connection Verification: Confirmation of proper electrical continuity to ground

- Load Capacity Compliance: Ensuring shelves are not overloaded in a way that compromises structure

- Visual Inspection: Regular examination for damage that might compromise ESD protection

- Documentation: Maintaining records of all testing and verification activities

These protocols ensure continued effectiveness of the ESD protection investment.

Hall-Fast: Award-Winning Global Provider of Eclipse® ESD Solutions

Hall-Fast has established itself as a premier global supplier of Eclipse® Chrome Wire ESD Shelving and comprehensive ESD protection solutions. As a family-owned business serving customers in over 150 countries, Hall-Fast combines international reach with personalized service.

International Recognition and Excellence

Hall-Fast's commitment to exceptional service and product quality has earned numerous prestigious awards, including recognition for:

- Outstanding international trade performance

- Business excellence in various sectors

- Innovation in industrial supply solutions

- Customer service excellence

For a complete list of Hall-Fast's impressive achievements, visit their Awards page.

Community Commitment and Corporate Responsibility

Beyond their business success, Hall-Fast remains deeply committed to community engagement, with initiatives including:

- Supporting local sports teams and youth programs

- Sponsoring charitable events and community development

- Contributing to educational initiatives

- Participating in environmental sustainability programs

This commitment to social responsibility reflects Hall-Fast's values as a family-owned business. Learn more about their community contributions on their Community page.

Comparing Eclipse® Chrome Wire ESD Shelving Options

Hall-Fast offers several Eclipse® Chrome Wire ESD Shelving configurations to address diverse application requirements:

- Standard Eclipse® Chrome Wire ESD Shelving (610mm Deep)

The 610mm deep Eclipse® Chrome Wire ESD Shelving represents the most versatile configuration, offering:

- Optimal Depth for Standard Components: Accommodating most electronic assemblies and components

- Maximum Load Capacity: Supporting up to 350kg per shelf evenly distributed

- Efficient Space Utilization: Balancing storage capacity with aisle access requirements

- Compatibility with Standard Containers: Accommodating industry-standard tote sizes

This configuration is ideal for general electronics manufacturing and storage applications where standard component sizes predominate.

- Additional Eclipse® ESD Shelving Configurations

Hall-Fast also offers complementary Eclipse® ESD shelving options including:

- 455mm Deep Shelving: For smaller components or space-constrained environments

- 914mm Deep Shelving: For larger assemblies or bulkier components

- Mobile Shelving Units: Featuring ESD-compliant castors for dynamic storage requirements

- High-Density Storage Systems: Utilizing track systems for maximum space efficiency

- Custom Configurations: Tailored solutions for unique application requirements

The complete range ensures organizations can implement precisely the right ESD shelving solution for their specific needs.

Conclusion: Eclipse® Chrome Wire ESD Shelving - The Foundation of Comprehensive ESD Protection

In environments where electrostatic discharge threatens product quality and reliability, Eclipse® Chrome Wire ESD Shelving from Hall-Fast provides the storage foundation for comprehensive protection programs. By implementing these specialized shelving systems, organizations ensure that components and assemblies remain protected throughout their entire production lifecycle.

The superior design, exceptional durability, and reliable ESD protection of Eclipse® shelving make it the preferred choice for electronics manufacturers, semiconductor fabricators, medical device producers, and aerospace/defence contractors worldwide. When integrated with complementary solutions like Eclipse® Chrome ESD Workbenches and appropriate personnel grounding systems, these shelving units create a complete protected environment.

Hall-Fast's international reach, award-winning service, and family business values make them the ideal partner for implementing Eclipse® ESD shelving solutions in any facility worldwide. Their technical expertise, commitment to quality, and global distribution capabilities ensure organizations receive both superior products and exceptional support.

For more information about Eclipse® Chrome Wire ESD Shelving and comprehensive ESD protection solutions for your specific industry needs, contact Hall-Fast to discuss your requirements with their knowledgeable team. Their extensive range of high-quality brands including the complete Eclipse® ESD product line ensures you'll find the right ESD protection solutions for your organization anywhere in the world.

Hall-Fast - Whatever Your Industry Needs Worldwide!