Your Definitive Buyer’s Guide to Compact, Efficient, and Emission-Free Material Handling for Small to Medium Warehouses, Workshops, and Retail Operations

Introduction: Why the 1000kg Electric Forklift Truck Is the Smart Choice for Compact Operations

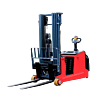

The 1000kg electric forklift truck has rapidly established itself as one of the most practical and cost-effective material handling solutions available to UK businesses. Designed for operations where space is limited, loads are moderate, and efficiency is paramount, this compact yet capable machine fills a critical gap between manual handling equipment and the larger, heavier forklifts associated with full-scale warehouse operations.

For small to medium-sized warehouses, retail stockrooms, workshops, manufacturing cells, and e-commerce fulfilment centres, the 1000kg electric forklift truck delivers exactly the right amount of lifting power without the unnecessary bulk, energy consumption, or expense of higher-capacity alternatives. Its compact dimensions allow it to operate in aisles and spaces that would be inaccessible to larger machines, while its electric powertrain ensures zero direct emissions, ultra-quiet operation, and dramatically lower running costs compared to diesel or LPG-powered equipment.

In this comprehensive guide, we explore every aspect of the 1000kg electric forklift truck in detail. From core specifications, key features, and battery technology through to UK regulatory requirements, operator training, maintenance strategies, and total cost of ownership, this article provides everything you need to make a confident and informed purchasing decision. Whether you are investing in your first forklift or adding a compact, agile machine to an existing fleet, this guide will help you understand exactly why the 1000kg electric forklift truck is the ideal solution for your business.

What Is a 1000kg Electric Forklift Truck?

Understanding the 1000kg Capacity Class

A 1000kg electric forklift truck is a battery-powered industrial vehicle engineered to lift, transport, and stack loads weighing up to 1,000 kilograms. The rated capacity is measured at a standard load centre distance, typically 500mm from the vertical face of the forks to the centre of gravity of the load. This industry-standard measurement ensures consistency and allows warehouse managers and operators to reliably assess whether any given load falls within the safe working limits of the machine.

The 1000kg capacity class occupies a strategically important position at the lighter end of the counterbalance forklift spectrum. It sits above pedestrian-operated pallet trucks and stackers, which are typically limited to simple horizontal transport or modest lift heights, and below the 1,500kg to 2,000kg forklifts that dominate mainstream warehouse operations. This positioning makes the 1000kg electric forklift truck uniquely suited to environments where loads are consistently moderate in weight but still require the versatility of a true forklift, including the ability to lift pallets to racking heights, load and unload vehicles, and navigate complex facility layouts.

Typical loads that fall comfortably within the 1000kg capacity include partially loaded Euro pallets, quarter pallets, lightweight consumer goods, packaged electronics, textile bales, stationery and office supplies, pharmaceutical products, and a wide range of boxed or shrink-wrapped merchandise. For many retail, light industrial, and service-sector businesses, the 1000kg electric forklift truck handles the majority of daily material handling tasks with ease, offering a genuine alternative to manual labour, platform trucks, and over-specified heavier forklifts.

Electric Power: The Foundation of Modern Compact Forklifts

The defining characteristic that sets the 1000kg electric forklift truck apart from internal combustion engine counterparts is its battery-powered electric drivetrain. Rather than burning diesel fuel or liquefied petroleum gas to generate mechanical power, the electric forklift draws energy from a rechargeable battery pack, typically operating at 24V, 48V, or 80V depending on the model and specification. This clean, quiet power source underpins the machine’s suitability for indoor environments, its minimal maintenance requirements, and its exceptionally low operating costs.

Electric power is not merely an environmental preference; it is a practical one. The instant torque delivery of electric motors provides smooth, responsive acceleration and precise speed control—characteristics that are particularly valuable when operating in confined spaces, positioning loads with accuracy, or navigating alongside pedestrians and other equipment. The absence of a gearbox, clutch, exhaust system, and complex engine components means fewer parts to wear out, fewer scheduled service intervals, and significantly lower lifetime maintenance expenditure.

How the 1000kg Electric Forklift Truck Compares to Diesel and LPG Alternatives

The advantages of the 1000kg electric forklift truck over diesel and LPG alternatives are substantial. The most immediately apparent difference is the elimination of exhaust emissions. Diesel forklifts produce carbon monoxide, nitrogen oxides, and particulate matter, all of which pose health risks in enclosed spaces. LPG forklifts, while cleaner-burning than diesel, still generate carbon monoxide and other combustion by-products. The 1000kg electric forklift truck produces zero tailpipe emissions, making it the only truly viable option for indoor use in environments where air quality is regulated or employee health is a priority.

Noise is another critical differentiator. A diesel forklift can generate noise levels of 85 to 100 decibels during operation, requiring hearing protection in many settings and limiting hours of use in noise-sensitive locations. The 1000kg electric forklift truck operates at substantially lower noise levels, typically below 70 decibels, enabling productive work during early morning, late evening, or overnight shifts without disturbing neighbouring businesses or residential properties. This quiet operation also improves communication between workers on the warehouse floor, contributing directly to safety.

Key Features and Technical Specifications

Load Capacity and Stability

The 1000kg rated load capacity provides ample lifting power for the majority of light to medium-duty material handling tasks. Stability is maintained through a carefully engineered counterbalance system, where the weight of the battery pack and the rear-mounted counterweight offset the load carried on the forks. This design ensures the forklift remains stable during lifting, lowering, and transport operations, provided that the rated capacity and load centre specifications are respected.

It is essential for operators and supervisors to understand that the rated capacity is the maximum safe working load under ideal conditions. Factors such as an elevated load centre, uneven weight distribution, lifting to height, operating on slopes, and the use of fork attachments can all reduce the effective capacity. Comprehensive operator training covers these variables and ensures that personnel can assess loads and operating conditions accurately before commencing any lifting operation.

Mast Configurations and Lift Heights

The 1000kg electric forklift truck is available with a variety of mast configurations to accommodate different operational requirements. Standard two-stage masts typically offer lift heights of 2,500mm to 3,300mm, sufficient for most ground-level and first-tier racking applications. For operations requiring higher stacking capability, three-stage triple telescopic masts extend the reach to 4,000mm or 4,500mm, while maintaining a compact collapsed height that allows the forklift to operate under low doorways, inside shipping containers, and beneath mezzanine floors.

The full free-lift feature, available on many triple mast models, allows the forks to be raised to a significant height before the outer mast sections begin to extend. This is a crucial specification for operations involving standard shipping containers, where the internal height clearance is limited. With full free-lift, the operator can raise the forks to the level required to clear a pallet in the container without the mast top exceeding the container ceiling height.

When selecting a mast configuration, consider not only the maximum lift height required but also the collapsed height, the free-lift height, and the overall stability of the forklift at maximum extension. Over-specifying the mast height adds unnecessary weight and cost, while under-specifying may limit operational flexibility in the future.

Compact Dimensions and Exceptional Manoeuvrability

One of the most compelling advantages of the 1000kg electric forklift truck is its compact footprint. With overall lengths typically ranging from 2,200mm to 2,800mm including forks and widths of 900mm to 1,050mm, these machines are significantly smaller than their 1,500kg and 2,000kg counterparts. This reduced footprint translates directly into superior manoeuvrability in confined operating environments.

The turning radius of a 1000kg electric forklift truck is typically in the range of 1,400mm to 1,800mm, enabling the machine to execute tight turns in narrow aisles that would be impassable for larger forklifts. Three-wheel models, which replace the conventional rear axle with a single drive and steer wheel, achieve even tighter turning circles, rivalling dedicated narrow-aisle equipment. For businesses operating in small warehouses, crowded stockrooms, or multi-use facilities where floor space is shared with production equipment, workbenches, or retail displays, this manoeuvrability is not merely convenient but essential.

The compact dimensions also make the 1000kg electric forklift truck an excellent choice for shipping container loading and unloading. The reduced height when the mast is collapsed allows the machine to enter standard-height containers, while the narrow body enables it to manoeuvre within the container’s width constraints.

Typical Specifications Overview

|

Specification |

Typical Range |

|

Rated Load Capacity |

1,000 kg at 500mm load centre |

|

Lift Height (Standard Mast) |

2,500 mm – 3,300 mm |

|

Lift Height (Triple Mast) |

3,500 mm – 4,500 mm |

|

Max Travel Speed (Unladen) |

12 – 15 km/h |

|

Max Travel Speed (Laden) |

10 – 13 km/h |

|

Turning Radius |

1,400 mm – 1,800 mm |

|

Maximum Gradeability |

12% – 17% |

|

Battery Type |

Lead-acid or Lithium-ion (24V – 80V) |

|

Overall Width |

900 mm – 1,050 mm |

|

Overall Length (incl. forks) |

2,200 mm – 2,800 mm |

|

Service Weight (incl. battery) |

1,800 kg – 2,800 kg |

|

Tyre Options |

Solid rubber, cushion, or pneumatic |

|

Fork Length |

920 mm – 1,150 mm |

Battery Technology: Lead-Acid vs Lithium-Ion

The choice of battery technology is one of the most significant decisions when specifying a 1000kg electric forklift truck. Lead-acid batteries remain the most affordable option at the point of purchase and are a well-proven technology with a long track record. However, they require regular maintenance including checking and topping up electrolyte levels with distilled water, cleaning terminals, and performing equalisation charges. Charging typically takes six to eight hours, followed by a cooling period before the forklift can return to service.

Lithium-ion batteries have transformed the electric forklift market in recent years. They offer faster charging times, often reaching full capacity in one to three hours, and support opportunity charging during natural breaks in the working day. This capability can eliminate the need for spare batteries and battery-changing infrastructure entirely. Lithium-ion batteries are also virtually maintenance-free, deliver consistent power output throughout the discharge cycle, and typically last two to three times longer than lead-acid batteries in total charge cycles.

For a 1000kg electric forklift truck operating in a single-shift environment with predictable usage patterns, a lead-acid battery may offer adequate performance at lower initial cost. For multi-shift operations, high-intensity use, or environments where downtime for charging is a commercial disadvantage, lithium-ion technology delivers a significantly better return on investment over the lifetime of the machine.

Ergonomics and Operator Comfort

Despite their compact dimensions, modern 1000kg electric forklift trucks are designed with genuine attention to operator ergonomics. Adjustable seats, tilt-adjustable steering columns, and intuitively positioned hydraulic controls reduce fatigue during prolonged use. The low centre of gravity and smooth electric drive system minimise whole-body vibration, protecting operators from the musculoskeletal strain associated with long hours of forklift operation.

The dashboard typically features a clear digital display providing real-time information on battery charge level, operating hours, fault codes, and speed. Many models include programmable performance settings, allowing supervisors to configure maximum travel speeds, acceleration rates, and lift speeds according to operator skill level and working environment requirements. Safety features such as curve control systems, anti-roll protection, seat belts, reverse alarms, and blue spot warning lights are increasingly offered as standard equipment.

Advantages of Choosing a 1000kg Electric Forklift Truck

Zero Emissions for Healthier Workplaces

The 1000kg electric forklift truck produces absolutely no direct emissions during operation. In enclosed environments such as warehouses, stockrooms, retail back-of-house areas, food processing facilities, and pharmaceutical storage spaces, this characteristic is essential. Diesel and LPG forklifts release exhaust gases including carbon monoxide, nitrogen oxides, and particulate matter, which accumulate in poorly ventilated spaces and pose significant health risks. By eliminating these emissions entirely, the 1000kg electric forklift truck creates a fundamentally healthier working environment and reduces the employer’s exposure to occupational health claims.

This advantage extends beyond employee welfare into commercial territory. Operations in the food and beverage sector, pharmaceutical manufacturing, and clean room environments increasingly require emission-free material handling equipment to meet hygiene standards, regulatory requirements, and customer audit criteria. Choosing a 1000kg electric forklift truck ensures compliance with these standards without the need for expensive ventilation systems or operational restrictions.

Ultra-Low Operating Costs

The financial advantages of the 1000kg electric forklift truck are particularly striking when compared to internal combustion alternatives on a cost-per-operating-hour basis. Electricity is substantially cheaper than diesel fuel or LPG per unit of energy delivered, and the smaller battery packs used in 1000kg machines consume correspondingly less energy per shift. Typical electricity costs for running a 1000kg electric forklift truck range from £0.50 to £1.00 per operating hour, compared to £2.50 to £4.50 per hour for an equivalent diesel machine.

Maintenance costs follow a similar pattern. The electric drivetrain eliminates the need for engine oil changes, fuel filters, air filters, exhaust system maintenance, cooling system servicing, and clutch or transmission repairs. The regenerative braking systems incorporated into many electric forklifts also extend the life of mechanical brake components. Over a typical operating life of 8,000 to 12,000 hours, the cumulative maintenance savings can amount to thousands of pounds, contributing to a total cost of ownership that is often 30 to 50 percent lower than diesel equivalents.

Whisper-Quiet Operation

The exceptionally low noise output of the 1000kg electric forklift truck, typically below 70 decibels, opens up operational possibilities that would be impractical with diesel or LPG equipment. Businesses can operate during early morning, late evening, or overnight hours without generating noise complaints from neighbours. In shared commercial premises, office-adjacent warehouses, and retail environments, the quiet operation allows material handling to continue during business hours without disturbing customers, clients, or office workers.

From a safety perspective, lower noise levels improve the ability of operators and nearby workers to communicate verbally and to hear audible warning signals such as horns, reversing alarms, and fire alarms. This contributes to a safer overall working environment and reduces the risk of accidents caused by impaired situational awareness.

Space Efficiency: Do More in Less Space

The compact dimensions of the 1000kg electric forklift truck allow businesses to maximise the productive use of their available floor space. In a small warehouse or stockroom, the ability to operate in narrower aisles means that racking can be positioned closer together, increasing storage density without sacrificing accessibility. For businesses renting commercial space at a premium per-square-metre cost, the space savings enabled by a compact forklift can translate directly into reduced property costs or increased storage capacity within the same footprint.

This space efficiency extends to the charging and storage of the forklift itself. A 1000kg electric forklift truck requires significantly less floor space for parking and charging than a larger machine, and the absence of fuel storage requirements eliminates the need for bunded diesel tanks or LPG cylinder storage areas, further freeing up valuable space within your facility.

Sustainability and Corporate Responsibility

Adopting a 1000kg electric forklift truck contributes directly to a business’s environmental performance and sustainability objectives. With zero direct carbon emissions and significantly lower energy consumption than internal combustion alternatives, electric forklifts support measurable reductions in scope 1 and scope 2 greenhouse gas emissions. For businesses pursuing ISO 14001 environmental management certification, B Corp status, or reporting under ESG frameworks, the transition to electric material handling equipment provides auditable progress towards environmental targets.

The growing emphasis on supply chain sustainability means that many larger organisations now assess the environmental practices of their suppliers and partners. Demonstrating a commitment to zero-emission equipment can strengthen your competitive position in tender processes and business development activities, particularly within public sector procurement and sectors with established sustainability reporting requirements.

Ideal Applications and Industries for the 1000kg Electric Forklift Truck

Small to Medium Warehouses and Distribution Centres

The 1000kg electric forklift truck is perfectly matched to the needs of small to medium-sized warehouses handling light to moderate loads. In these environments, the majority of palletised goods weigh between 300kg and 900kg, comfortably within the machine’s capacity. The compact footprint allows efficient operation in the narrower aisles common to smaller facilities, while the electric powertrain keeps energy costs low and indoor air quality high.

Retail Stockrooms and Back-of-House Operations

Retail businesses, supermarkets, and department stores frequently need to move palletised stock from delivery vehicles to stockrooms and onwards to the shop floor. The 1000kg electric forklift truck handles these tasks efficiently, quietly, and safely. Its compact size navigates the often cluttered and constrained spaces found in retail back-of-house areas, while the zero-emission operation ensures compliance with indoor air quality standards and protects the comfort of nearby customers and staff.

Light Manufacturing, Assembly, and Workshops

Manufacturing workshops and assembly lines handling components, sub-assemblies, and finished products weighing up to 1,000kg benefit from the precision and agility of this forklift class. The smooth electric drive allows careful positioning of delicate or valuable components, and the quiet operation supports concentration and communication in production environments. The compact dimensions allow the forklift to operate within the tight layouts typical of workshop environments, where space is shared with machinery, workbenches, and storage systems.

Printing, Publishing, and Paper Handling

The printing and publishing industry handles rolls of paper, printed materials, and palletised publications that frequently fall within the 1000kg capacity range. The 1000kg electric forklift truck provides the lift capability needed to stack and retrieve these materials while maintaining the clean, emission-free environment required to protect printed products from contamination by exhaust fumes or particulate matter.

Food, Beverage, and Cold Storage

In food storage and distribution facilities, the 1000kg electric forklift truck meets the strict hygiene and air quality requirements that govern these environments. The absence of exhaust fumes eliminates the risk of product contamination, while the low noise levels support comfortable working conditions in temperature-controlled spaces where ventilation may be limited. Cold storage specification packages including heated operator cabins and condensation-resistant electronics are available for many models to ensure reliable performance in chilled and frozen environments.

E-Commerce Fulfilment and Parcel Operations

The rapid growth of online retail has created vast networks of fulfilment centres handling high volumes of individually picked and packed orders. Many of these facilities handle goods that weigh well under 1,000kg per pallet, making the 1000kg electric forklift truck an ideal fit. Its manoeuvrability in tight spaces, rapid cycle times, and low energy consumption contribute to the operational efficiency that e-commerce businesses depend on to remain competitive in an increasingly demanding marketplace.

Healthcare, Education, and Institutional Facilities

Universities, hospitals, research facilities, and other institutional settings often have material handling requirements that fall below the capacity of standard warehouse forklifts. The 1000kg electric forklift truck provides a proportionate solution for moving supplies, equipment, furniture, and materials within these environments, where quiet operation and zero emissions are particularly valued. Its compact dimensions are well-suited to the corridors, lifts, and storage areas found in institutional buildings.

UK Regulations and Legal Requirements for Electric Forklift Operations

Health and Safety at Work Act 1974

The Health and Safety at Work Act 1974 is the overarching legislation governing workplace safety in the United Kingdom. It places a general duty on employers to ensure, so far as is reasonably practicable, the health, safety, and welfare of their employees. This duty encompasses the selection, maintenance, and operation of all workplace equipment, including the 1000kg electric forklift truck. The Act also established the Health and Safety Executive (HSE), the body responsible for enforcing workplace safety standards and providing guidance to employers and employees across all sectors.

LOLER: Lifting Operations and Lifting Equipment Regulations 1998

LOLER applies directly to forklift trucks and requires that all lifting operations are properly planned by a competent person, appropriately supervised, and carried out safely. The regulations mandate that forklift trucks undergo a thorough examination by a competent person at intervals not exceeding 12 months. If the forklift is used to lift people using an approved work platform, the examination interval is reduced to 6 months. Employers must retain records of all thorough examinations and take immediate action to address any defects identified during the inspection process.

PUWER: Provision and Use of Work Equipment Regulations 1998

PUWER requires that all work equipment, including 1000kg electric forklift trucks, is suitable for its intended use, maintained in a safe condition, and operated only by persons who have received adequate training and instruction. The regulations also require that employers maintain a documented log of all inspections, servicing, and repairs carried out on the equipment. Together with LOLER, PUWER forms the regulatory framework that ensures forklift trucks are safe, well-maintained, and operated competently throughout their working life.

Operator Training and Certification

UK law requires that all forklift truck operators complete an accredited training programme before operating any forklift in the workplace. There is no formal government-issued forklift licence in the UK; instead, operators receive a certificate of training from an accredited provider upon successful completion of the programme. Training is categorised by truck type, with separate certifications required for counterbalance forklifts, reach trucks, pallet trucks, and other equipment categories.

For the 1000kg electric forklift truck, operators typically need a counterbalance forklift training certificate. A full novice training course usually spans three to five days and covers pre-operational checks, safe driving techniques, load assessment, stacking and de-stacking procedures, and emergency protocols. Operators who already hold a valid counterbalance certificate for a diesel or LPG forklift may require a shorter conversion course to familiarise themselves with the specific characteristics of electric operation, including battery management, regenerative braking, and the absence of engine noise cues.

Employers are strongly advised to schedule refresher training at intervals of three to five years to maintain operator competency. Penalties for permitting untrained operators to use forklift trucks can include fines of up to twenty thousand pounds, prosecution under health and safety legislation, and significant reputational damage to the business.

Battery Safety and Charging Compliance

The operation and charging of forklift batteries is subject to specific health and safety guidance from the HSE. Lead-acid batteries, which produce hydrogen gas during charging, must be charged in a designated area with adequate ventilation to prevent the accumulation of flammable gas. The charging area should be equipped with appropriate fire extinguishing equipment, eye wash facilities, and spill containment provisions. Lithium-ion batteries require less stringent environmental controls but must be charged using the manufacturer-specified charger and in accordance with documented procedures to prevent thermal incidents.

How to Choose the Right 1000kg Electric Forklift Truck for Your Business

Assessing Your Operational Requirements

Selecting the ideal 1000kg electric forklift truck begins with a detailed assessment of your operational needs. Start by documenting the typical weight and dimensions of the loads you handle most frequently. If the overwhelming majority of your loads fall comfortably below 1,000kg, this capacity class will serve you well. If you regularly encounter loads approaching or exceeding the 1,000kg threshold, it may be prudent to consider a 1,500kg model to provide a margin of safety and operational flexibility.

Next, evaluate the physical environment in which the forklift will operate. Measure the aisle widths, doorway dimensions, ceiling heights, and turning spaces available in your facility. The compact dimensions of the 1000kg electric forklift truck make it suitable for spaces as narrow as 2,800mm to 3,200mm for right-angle stacking with a standard pallet, but confirming this against your actual facility layout is essential before committing to a purchase.

Three-Wheel vs Four-Wheel Configuration

Three-wheel 1000kg electric forklift trucks offer the tightest possible turning circle and are the preferred choice for operations conducted primarily indoors on smooth, level surfaces. The single rear wheel provides exceptional agility, enabling the machine to pivot in spaces that would challenge a four-wheel model. However, the three-wheel configuration offers slightly less lateral stability, which may be a consideration if the forklift will be used on uneven surfaces, outdoor yards, or loading docks with dock levellers.

Four-wheel models provide greater overall stability and are better suited to mixed indoor-outdoor applications, operations on less-than-perfect floor surfaces, and environments where the forklift may encounter ramps, thresholds, or uneven terrain. If your operation involves significant outdoor work or dock-to-vehicle loading, a four-wheel configuration is likely the safer and more practical choice.

Tyre Selection: Solid, Cushion, or Pneumatic

Tyre choice should be guided by the surfaces on which the 1000kg electric forklift truck will predominantly operate. Solid rubber tyres offer excellent durability and puncture resistance, making them ideal for indoor use on smooth concrete floors and in environments where debris or sharp objects may be present. Cushion tyres provide a lower ride height, beneficial in facilities with restricted overhead clearance. Pneumatic tyres deliver the best ride comfort and traction on rough, uneven, or outdoor surfaces.

Non-marking tyre compounds are available for environments where floor cleanliness is important, such as food preparation areas, pharmaceutical facilities, and retail showrooms. These tyres provide the same performance characteristics as standard rubber compounds without leaving black marks on light-coloured flooring.

Matching Battery Capacity to Your Duty Cycle

Selecting the correct battery capacity is critical for maintaining productivity throughout each shift. A battery that is too small will run flat before the shift ends, forcing an unproductive charging break or costly battery swap. Conversely, an over-specified battery adds unnecessary weight and purchase cost. Calculate the total operating hours required per shift, multiply by the average power consumption of the forklift, and select a battery with sufficient capacity to cover the shift with a reasonable reserve margin of approximately fifteen to twenty percent.

For lithium-ion systems, the ability to opportunity-charge during breaks provides additional flexibility, often allowing a smaller and lighter battery to cover the same operational period as a larger lead-acid unit. This weight advantage can also improve the forklift’s manoeuvrability and reduce tyre wear.

Optional Equipment and Attachments

The versatility of the 1000kg electric forklift truck can be enhanced with a range of optional equipment. Side shift carriages allow lateral adjustment of the forks without repositioning the entire machine, improving precision when placing pallets in tight racking bays. Fork positioners provide hydraulic adjustment of fork spacing for handling pallets of varying widths. Integrated weighing systems display the load weight on the operator’s dashboard, supporting load management and compliance with capacity limits.

Safety accessories include blue spot warning lights that project a visible marker on the floor ahead of or behind the moving forklift, LED work lights for improved visibility in dimly lit areas, reversing cameras for enhanced rearward vision, and audible reversing alarms. These features are increasingly specified as standard on new machines and represent a worthwhile investment in workplace safety.

Maintenance and Care for Long-Term Reliability

Daily Pre-Operational Checks

Every shift should begin with a structured pre-operational check carried out by the operator. This check should include a visual inspection of the forks for cracks, bending, or excessive wear; testing the mast and carriage for smooth, unrestricted movement; checking the horn, lights, and reversing alarm; inspecting the tyres for damage, wear, or incorrect pressure; testing the service brake and parking brake; verifying the battery charge level; and examining the forklift for any visible leaks, loose components, or damage.

Any defects identified during the pre-operational check should be reported immediately, and the forklift should not be used until the defect has been rectified by a qualified technician. Maintaining a written or digital log of daily checks demonstrates compliance with PUWER and provides documentary evidence of due diligence in the event of an incident or HSE inspection.

Scheduled Preventive Maintenance

The manufacturer’s recommended maintenance schedule should be followed rigorously. Typical service intervals range from every 250 to 500 operating hours, depending on the intensity of use and operating environment. Scheduled servicing generally includes inspection and adjustment of the braking system, lubrication of mast chains and rollers, inspection of hydraulic hoses, cylinders, and fluid levels, testing of all electrical connections and wiring, inspection of the steering system, and a functional test of all safety systems.

Lithium-ion battery systems require minimal scheduled maintenance beyond periodic inspection of the battery management system and verification of charger function. Lead-acid batteries demand more frequent attention, including regular electrolyte level checks, terminal cleaning, and equalisation charging. Regardless of battery type, following the manufacturer’s battery care guidelines will maximise battery lifespan and ensure consistent performance throughout the working day.

LOLER Thorough Examinations

The mandatory thorough examination under LOLER must be carried out by a competent person at intervals not exceeding 12 months. This examination goes beyond routine servicing and involves a detailed assessment of all structural components, load-bearing elements, safety devices, and operational systems. The competent person will issue a written report identifying any defects and specifying the timeframe within which they must be addressed. Employers must retain these reports and act on any recommendations promptly to remain compliant.

Total Cost of Ownership: Understanding the Financial Case

Initial Investment vs Lifetime Value

The purchase price of a 1000kg electric forklift truck may be comparable to or slightly higher than an equivalent diesel or LPG machine, depending on the specification and battery technology selected. However, the initial purchase price represents only a fraction of the total cost of ownership. When energy costs, maintenance expenses, battery replacement, downtime, and residual value are factored in, the 1000kg electric forklift truck consistently delivers a lower total cost over its operational life.

Running Cost Comparison: Electric vs Diesel

|

Cost Factor |

Electric (Li-ion) |

Diesel |

|

Energy/Fuel Cost per Hour |

£0.50 – £1.00 |

£2.50 – £4.50 |

|

Annual Energy/Fuel (1,500 hrs) |

£750 – £1,500 |

£3,750 – £6,750 |

|

Annual Maintenance |

£500 – £1,200 |

£1,500 – £3,000 |

|

Estimated 5-Year Running Cost |

£6,250 – £13,500 |

£26,250 – £48,750 |

These figures are illustrative estimates based on typical UK energy costs and servicing rates. Your actual costs will vary depending on usage intensity, local energy tariffs, and the specific maintenance arrangements in place. However, the direction of the comparison is clear: the 1000kg electric forklift truck delivers dramatically lower running costs over its operational lifetime, with five-year savings frequently exceeding £20,000 compared to a diesel equivalent.

Residual Value and End-of-Life Considerations

Quality electric forklifts tend to retain their value well on the used equipment market. The increasing demand for zero-emission material handling equipment, coupled with the inherently lower wear on electric drivetrains, means that a well-maintained 1000kg electric forklift truck can command an attractive resale price at the end of its primary service life. Lithium-ion equipped models are particularly sought-after, as the battery technology carries significant residual value and appeals to buyers seeking modern, low-maintenance equipment.

Safety Best Practices for Operating a 1000kg Electric Forklift Truck

Operator Conduct and Awareness

Safe operation of the 1000kg electric forklift truck depends on the attentiveness, training, and discipline of the operator. Fundamental safety practices include maintaining a clear line of sight at all times, travelling in reverse when the load obstructs forward vision, sounding the horn at blind corners and intersections, observing posted speed limits, keeping hands and feet within the operator compartment, and never carrying passengers unless the machine is equipped with an approved passenger seat.

Load Handling and Stability

Operators should always verify that the load weight is within the rated capacity before lifting. Loads should be centred on the forks, with the forks fully inserted under the pallet. During transport, the load should be carried as low as practical and tilted slightly back against the mast carriage to maximise stability. When stacking at height, the operator should approach the racking slowly, raise the load to the required height, and tilt the mast forward only when the forks are directly positioned over the racking beams.

Pedestrian Safety

Managing the interaction between forklifts and pedestrians is one of the most significant safety challenges in any workplace. Best practice calls for physical separation of forklift routes and pedestrian walkways wherever possible. Where separation is impractical, clearly marked crossing points, warning signs, floor markings, barriers, and blue spot safety lights should be implemented. Operators should sound the horn when approaching areas where pedestrians may be present and reduce speed whenever visibility is limited.

Battery Charging Safety

Charging operations should take place in a designated, ventilated area with appropriate safety equipment readily accessible. Operators should be trained in the correct procedures for connecting and disconnecting charging cables, the safe handling of batteries, and the emergency response protocols for battery spills or thermal events. Smoking, naked flames, and other ignition sources must be strictly prohibited in battery charging areas at all times.

Why Buy Your 1000kg Electric Forklift Truck from Hall-Fast

Hall-Fast is a well-established and trusted supplier of industrial and commercial equipment to businesses throughout the United Kingdom. With decades of experience in the material handling sector and a commitment to providing expert advice, competitive pricing, and reliable nationwide delivery, Hall-Fast is the ideal partner for your 1000kg electric forklift truck purchase.

When you buy from Hall-Fast, you gain access to a knowledgeable team that understands the practical requirements of compact material handling operations. Whether you need guidance on selecting the right mast height, choosing between three-wheel and four-wheel configurations, comparing battery technologies, or identifying the most appropriate optional equipment for your facility, Hall-Fast’s specialists are available to help you make the right decision with confidence.

Hall-Fast’s comprehensive product range extends beyond forklifts to encompass the full spectrum of handling and lifting equipment, including pallet trucks, stackers, platform trucks, forklift attachments, safety cages, and warehouse safety products. This means you can source your complete material handling solution from a single trusted supplier, simplifying procurement, ensuring compatibility across your fleet, and benefiting from a consolidated relationship with a responsive and experienced equipment partner.

Frequently Asked Questions About the 1000kg Electric Forklift Truck

Is a 1000kg electric forklift truck powerful enough for a standard warehouse?

For warehouses handling light to moderate loads, the 1000kg electric forklift truck is an excellent choice. A standard Euro pallet loaded with consumer goods, packaged products, or light industrial components typically weighs between 300kg and 900kg, well within the machine’s capacity. If your operation regularly handles loads exceeding 1,000kg, a higher-capacity model such as a 1500kg electric forklift truck may be more appropriate.

How long does the battery last on a single charge?

Battery life varies depending on the battery type, capacity, and intensity of use. A well-specified lithium-ion battery can power a 1000kg electric forklift truck through a full eight-hour shift of typical warehouse work. Lead-acid batteries provide similar runtime but require a longer recharging period of six to eight hours. Lithium-ion systems also support opportunity charging during breaks, extending the effective operating window without requiring a full recharge cycle.

Can a 1000kg electric forklift truck be used outdoors?

Yes, provided the model is equipped with suitable tyres and the surface conditions are appropriate. Pneumatic tyres provide the best performance on rough or uneven outdoor surfaces. However, electric forklifts should not be operated in heavy rain, standing water, or extreme weather unless specifically rated for such conditions. For mixed indoor-outdoor use, discuss your requirements with the supplier to ensure the correct specification is selected.

What training do operators need in the UK?

All operators must complete an accredited counterbalance forklift training programme, which typically takes three to five days for novice operators or one to two days for experienced operators converting from diesel or LPG machines. Regular refresher training at three to five-year intervals is strongly recommended. There is no formal government-issued forklift licence in the UK; operators receive a certificate of training from the accredited training provider.

How does the 1000kg model compare to a 1500kg electric forklift truck?

The 1000kg electric forklift truck is smaller, lighter, more manoeuvrable, and less expensive to purchase and operate than a 1500kg model. It is the preferred choice for operations where loads consistently remain below 1,000kg and where compact dimensions and tight turning ability are priorities. The 1500kg model offers greater lifting capacity and is more suitable for operations handling heavier palletised goods or requiring a greater margin of capacity.

What is the expected lifespan?

With proper maintenance, a quality 1000kg electric forklift truck delivers reliable service for 8,000 to 12,000 operating hours. In a typical single-shift operation averaging 1,200 to 1,500 hours per year, this equates to a working life of approximately six to ten years. Lithium-ion batteries typically provide 2,000 to 5,000 charging cycles before significant capacity degradation, further supporting the long-term viability of the investment.

Is financing available?

Many suppliers and third-party finance providers offer a range of financing options including hire purchase, finance lease, operating lease, and contract hire. These options allow businesses to spread the cost over time, preserve working capital, and potentially benefit from tax advantages. Contact Hall-Fast to discuss the financing arrangements available for your purchase.

Conclusion: The 1000kg Electric Forklift Truck – Compact Power, Maximum Value

The 1000kg electric forklift truck represents the perfect balance of capability, efficiency, and economy for businesses that need reliable material handling without the size, cost, and complexity of larger equipment. Its compact dimensions unlock productivity in spaces where bigger machines simply cannot operate, while its electric powertrain delivers the cleanest, quietest