In the dynamic world of materials handling, versatility and adaptability are paramount for operational efficiency. Forklift extension forks have emerged as essential accessories that significantly expand the capabilities of standard forklifts, enabling them to handle oversized, long, or awkwardly shaped loads with greater safety and efficiency. This comprehensive guide explores the applications, benefits, selection criteria, and safety considerations associated with these versatile attachments.

Understanding Forklift Extension Forks

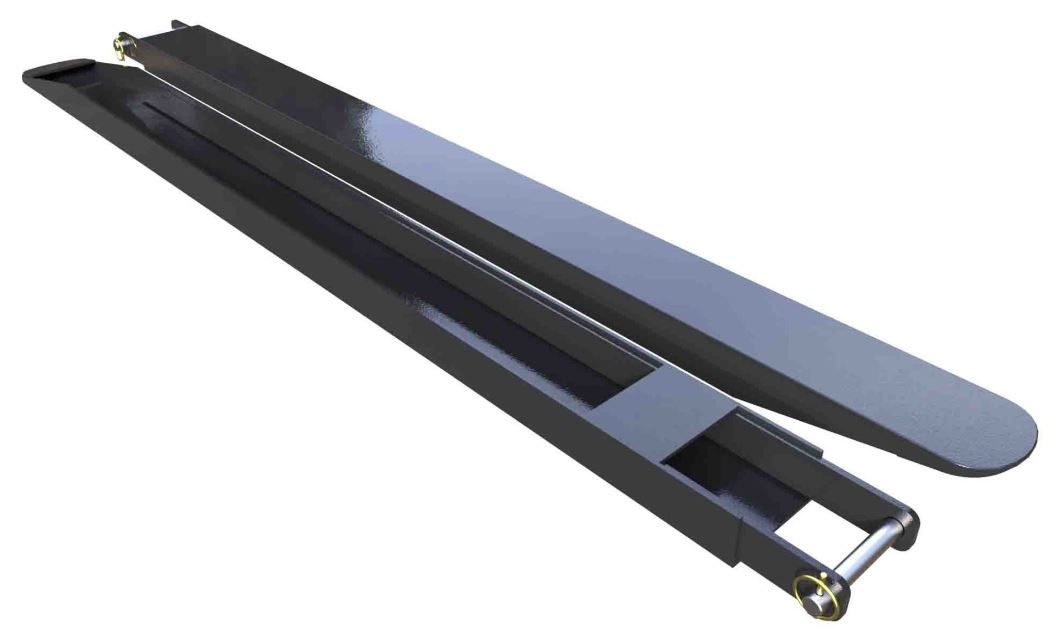

Forklift extension forks, also known as fork extenders or fork sleeves, are attachments designed to increase the effective length of standard forklift tines. They typically slide over existing forks and secure in place, instantly transforming a standard forklift into equipment capable of handling longer loads that would otherwise require specialized machinery.

These attachments are available in various configurations:

- Slip-on extensions: The most common type, designed to slide directly onto existing forks

- Pin-type extensions: Secured with pins for additional stability

- Folding extensions: Adjustable length for varied applications

- Telescopic extensions: Offering variable reach capabilities

- Specialized profile extensions: Designed for specific load types

The primary function of forklift extension forks is to distribute the weight of longer loads across a greater surface area, improving stability and reducing the risk of load tipping or slippage. This capability is particularly valuable when handling materials such as:

- Lumber and construction materials

- Pipework and tubing

- Carpet rolls and textiles

- Panel products and sheeting

- Oversized pallets and crates

- Long fabricated components

Key Benefits of Implementing Forklift Extension Forks

The strategic deployment of forklift extension forks delivers multiple operational advantages:

Enhanced Versatility

- Transform standard forklifts into multi-purpose equipment

- Handle diverse load types without dedicated machinery

- Adapt quickly to changing material handling requirements

- Reduce the need for specialized equipment purchases

Improved Operational Efficiency

- Decrease load handling time for oversized materials

- Reduce the need for multiple handling operations

- Enable direct loading and unloading of vehicles

- Optimize storage space utilization with deeper rack access

Significant Cost Reductions

- Minimize investment in specialized handling equipment

- Reduce labour costs associated with multiple handling steps

- Decrease product damage from improper handling

- Lower maintenance costs compared to specialized machinery

Enhanced Safety Performance

- Improve load stability for long or awkward items

- Reduce manual handling requirements and associated injuries

- Minimize the risk of load shifts during transport

- Provide appropriate support for materials that extend beyond standard pallets

Critical Selection Factors for Extension Forks

Choosing the appropriate forklift extension forks involves careful consideration of multiple factors to ensure optimal performance, safety, and compatibility:

Load Characteristics Assessment

- Maximum weight requirements

- Typical and maximum load lengths

- Load distribution patterns

- Material types and physical properties

- Special handling considerations (fragility, flexibility, etc.)

Forklift Compatibility

- Fork dimensions (width, thickness, length)

- Attachment method compatibility

- Load capacity implications (extension forks reduce effective capacity)

- Hydraulic or manual adjustment capabilities

- Visibility considerations during operation

Material and Construction Quality

- High-strength steel construction

- Reinforced sleeve design

- Wear resistance characteristics

- Surface treatments and corrosion protection

- Manufacturing quality and tolerance precision

Safety Features

- Secure locking mechanisms

- Heel reinforcement

- Visibility markings

- Anti-slip surfaces

- Load-stop designs to prevent over-insertion

Operational Environment

- Indoor vs. outdoor usage

- Exposure to corrosive elements

- Temperature extremes

- Surface conditions and terrain

- Space constraints and manoeuvrability requirements

Thorough evaluation of these factors ensures selected forklift extension forks deliver optimal performance while maintaining operational safety and equipment compatibility.

Safety Considerations and Best Practices

While forklift extension forks enhance handling capabilities, they also introduce specific safety considerations that must be addressed through proper training and operational protocols:

Load Capacity Adjustments Extension forks effectively create a longer lever arm, reducing the forklift's safe working load. Operators must understand and apply the appropriate load reduction calculations:

- At standard load centre (500mm/600mm): Typical capacity reduction of 30-50%

- At extended load centre: Additional proportional reduction based on distance

- With uneven load distribution: Further reductions may be necessary

Operational Protocols Safe operation requires specific procedures:

- Pre-use inspection: Check for damage, deformation, or excessive wear

- Proper installation: Ensure secure attachment and locking

- Load positioning: Centre loads whenever possible

- Movement protocols: Reduce speed and avoid sudden manoeuvres

- Height limitations: Lower handling heights may be necessary with extended loads

- Turning radius awareness: Account for increased load projection

- Floor condition assessment: Ensure surfaces can support concentrated loads

- Visibility accommodations: Implement spotters when necessary

Training Requirements Operators require specific training on:

- Extension fork installation and removal

- Load capacity recalculation

- Stability considerations with extended loads

- Movement restrictions and precautions

- Storage and maintenance procedures

Regulatory Compliance In the UK, the use of forklift extension forks must comply with:

- LOLER (Lifting Operations and Lifting Equipment Regulations 1998)

- PUWER (Provision and Use of Work Equipment Regulations 1998)

- The Health and Safety at Work Act 1974

- Manufacturer's specific guidance and limitations

- HSE recommendations for forklift attachments

Maintenance and Inspection Requirements

Maintaining forklift extension forks in optimal condition requires systematic inspection and maintenance protocols:

Regular Inspection Schedule

- Pre-use visual checks: For damage, deformation, or wear

- Weekly documented inspections: Focusing on locking mechanisms and structural integrity

- Monthly thorough examinations: Including wear measurements and weld inspection

- Annual certified inspections: Conducted by qualified personnel in accordance with LOLER

- Post-incident examinations: Following any impacts or suspected overloading

Key Inspection Points

- Sleeve integrity and internal wear

- Locking mechanism functionality

- Structural deformation or bending

- Weld integrity, especially at stress points

- Surface protection and corrosion evidence

- Heel condition and reinforcement

- Safety markings and visibility features

Maintenance Procedures

- Cleaning to remove debris and allow proper inspection

- Lubrication of moving components according to manufacturer specifications

- Repair of surface protection to prevent corrosion

- Replacement of worn or damaged components

- Documentation of all maintenance activities

Proper maintenance not only ensures safety but also significantly extends the service life of the equipment, improving the overall return on investment.

Sourcing Quality Forklift Extension Forks

When investing in forklift extension forks, partnering with established suppliers ensures both product quality and compliance with relevant standards. Hall-Fast offers an extensive range of certified forklift extensions designed to enhance operational capabilities while maintaining strict safety standards.

Their comprehensive selection includes options for diverse applications and fork dimensions, all manufactured to meet or exceed relevant regulatory requirements. For operations with unique requirements, custom-length extensions can be fabricated to address specific handling challenges.

For expert guidance on selecting the optimal extension forks for your specific operational needs, contact the Hall-Fast team directly at sales@hall-fast.com. Their specialists can assist in evaluating your requirements and recommending appropriate solutions that balance safety, efficiency, and value.

Conclusion

Forklift extension forks represent a cost-effective solution for expanding the capabilities of existing equipment, enabling organizations to handle a wider range of materials without significant investment in specialized machinery. By understanding the available options, selection criteria, and safety considerations, operations managers can make informed decisions that enhance productivity while maintaining workplace safety.

With proper selection, implementation, operator training, and maintenance, these versatile attachments deliver substantial operational benefits across diverse industries and applications. Whether handling construction materials, oversized components, or non-standard loads, extension forks provide the additional reach and support necessary for safe, efficient materials handling.