The Critical Role of Fasteners in Electric Vehicle Manufacturing

Electric vehicle (EV) production presents unique fastening challenges that differ significantly from traditional automotive manufacturing. The East Midlands, with Toyota's Burnaston plant and extensive automotive supply chains, is at the forefront of the UK's electric vehicle transition. Hall-Fast, through their comprehensive platform at https://www.hall-fast.com/fasteners-small-components, provides specialized electric vehicle fasteners meeting the exacting requirements of EV manufacturing, from battery assembly to high-voltage systems and lightweight construction.

Unique Requirements for Electric Vehicle Fasteners

Electrical Isolation and Safety

Electric vehicle fasteners must address critical electrical safety requirements:

- Insulated fasteners preventing electrical conductivity between components

- Non-conductive coatings for fasteners near high-voltage systems

- Specialized materials like ceramics or polymer-coated metals

- Torque-to-yield bolts ensuring consistent clamping forces in battery assemblies

- Thread-locking compounds compatible with electrical components

Battery Pack Assembly Fasteners

EV battery packs require specialized fastening solutions:

- Vibration-resistant fasteners preventing loosening over vehicle lifetime

- Thermal management - fasteners that maintain integrity across temperature ranges (-40°C to +85°C)

- Lightweight materials like aluminum and titanium reducing overall battery weight

- Precision torque specifications critical for battery cell compression

- Fire-resistant materials meeting stringent safety standards

- Sealed fasteners preventing moisture ingress into battery compartments

Thermal Management Considerations

Electric vehicles generate different heat patterns than combustion engines:

- Heat-dissipating fasteners for power electronics and motor assemblies

- Thermal barrier coatings preventing heat transfer

- Expansion-compatible designs accommodating thermal cycling

- High-temperature resistant materials for components near inverters and converters

Materials Technology for EV Fasteners

Lightweight Solutions

Weight reduction is crucial for extending EV range:

- Aluminum fasteners offering 60% weight reduction over steel

- Titanium fasteners providing maximum strength-to-weight ratio

- Carbon fiber reinforced plastics for non-structural applications

- Magnesium alloys for specific lightweight requirements

- Hollow fasteners reducing weight while maintaining strength

Corrosion Resistance

EVs face unique corrosion challenges from road salt and battery chemistry:

- Specialized coatings protecting against galvanic corrosion

- Stainless steel grades selected for compatibility with aluminum structures

- Zinc-nickel plating providing superior corrosion protection

- Ceramic coatings offering electrical isolation and corrosion resistance

Specific EV Applications

High-Voltage System Fasteners

- Orange-colored fasteners for high-voltage component identification

- Tamper-evident designs preventing unauthorized access

- Specialized torque specifications for electrical connections

- Materials tested for arc resistance and tracking

Electric Motor Assembly

- Non-magnetic fasteners preventing interference with motor operation

- High-strength fasteners handling motor torque reactions

- Precision fasteners maintaining rotor-stator alignment

- Vibration-dampening designs reducing noise transmission

Chassis and Body Integration

- Multi-material joining solutions for aluminum-steel combinations

- Flow drill screws for joining dissimilar materials

- Self-piercing rivets for mixed-material assemblies

- Adhesive-compatible fasteners for bonded joints

Standards and Compliance

Electric vehicle fasteners must meet additional standards beyond traditional automotive requirements:

- ISO 6469 - Electric vehicle safety specifications

- UN ECE R100 - Safety requirements for electric powertrains

- LV 123 - German automotive standard for high-voltage components

- USCAR specifications for EV applications

- IP67/IP69K - Ingress protection ratings for moisture and dust

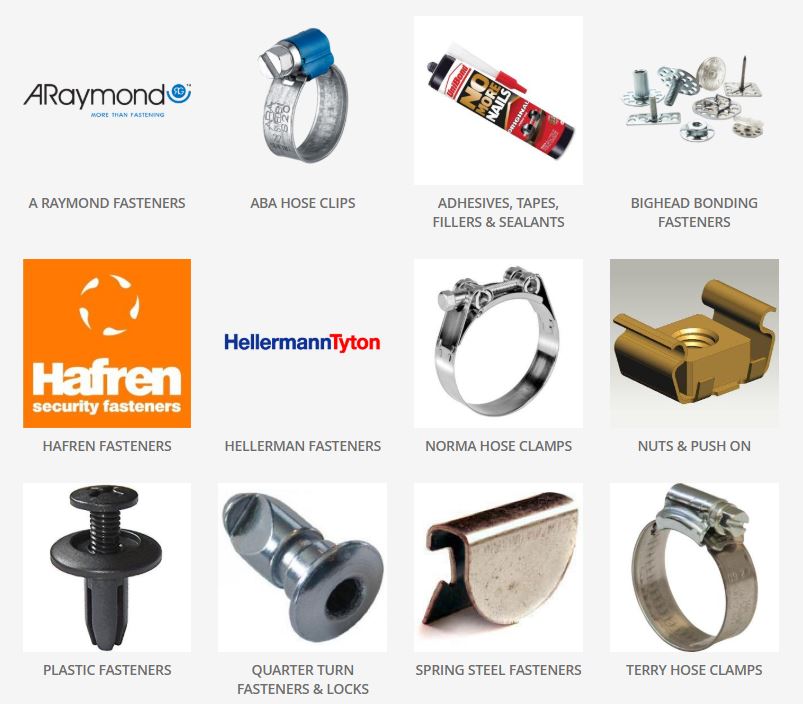

Hall-Fast's EV Fastener Solutions

Hall-Fast's comprehensive range includes specialized fasteners for every aspect of EV manufacturing:

- Complete battery pack fastening systems

- High-voltage electrical connection hardware

- Lightweight structural fasteners

- Thermal management system fasteners

- Charging system component fasteners

- EMC shielding fasteners

The company's Price Promise: 'We will not be beaten on price on any like for like product, if you find a better price anywhere on the internet or receive a quotation please let us know and we will match it!' ensures EV manufacturers achieve competitive pricing on these specialized components.

Supporting the East Midlands EV Transition

With Toyota and other manufacturers transitioning to electric vehicle production, Hall-Fast provides:

- Technical support for fastener selection in new EV designs

- Rapid prototyping support for development programs

- Volume production capability for series manufacturing

- Just-in-time delivery supporting lean production

- Compliance documentation for safety and quality requirements

Future Developments

As EV technology evolves, Hall-Fast continues expanding their range:

- Fasteners for solid-state battery assemblies

- Solutions for wireless charging system installation

- Autonomous vehicle sensor mounting systems

- Next-generation lightweight materials

- Recyclable fastener solutions supporting circular economy

Complementary Products for EV Manufacturing

At https://www.hall-fast.com/tools, find specialized tools for EV assembly:

- Insulated torque wrenches for high-voltage work

- Digital torque verification systems

- ESD-safe tools preventing component damage

The consumables range at https://www.hall-fast.com/consumables includes:

- Dielectric greases for electrical connections

- Thermal compounds for heat management

- Thread lockers compatible with EV materials

Safety equipment at https://www.hall-fast.com/safety-at-work ensures worker protection:

- Electrical insulation gloves and tools

- Arc flash protection equipment

- Specialized PPE for battery handling

Conclusion

Electric vehicle manufacturing represents a transformative opportunity for the East Midlands automotive sector. Hall-Fast's specialized electric vehicle fasteners, combined with technical expertise and comprehensive support, position them as the ideal partner for businesses navigating the EV transition. From prototype development to volume production, Hall-Fast delivers the fastening solutions essential for safe, efficient, and competitive electric vehicle manufacturing.

For more information about electric vehicle fasteners, visit https://www.hall-fast.com/fasteners-small-components or contact Hall-Fast at https://www.hall-fast.com/contact to discuss your specific EV fastening requirements.