Heavy-Duty Pallet Flow Roller Tracks: Dynamic Storage for High-Volume Operations

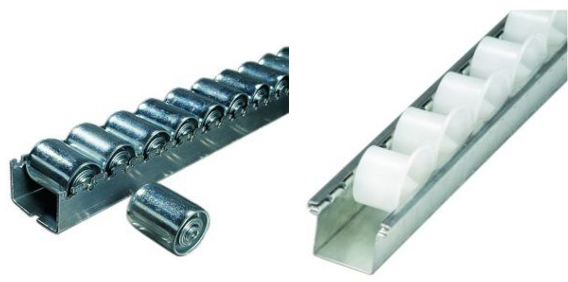

Pallet flow roller tracks represent specialized material handling infrastructure designed specifically for high-density pallet storage implementing FIFO (First-In, First-Out) inventory management. These robust systems combine substantial load capacity with precision flow control, creating self-replenishing pallet lanes that maximize storage density while ensuring proper stock rotation.

Hall-Fast supplies professional-grade pallet flow roller tracks engineered for demanding warehouse and distribution applications. Our systems incorporate heavy-duty components designed for the substantial loads and operational intensity typical in pallet handling environments, delivering reliable performance while minimizing maintenance requirements and maximizing operational lifespan.

The engineering principles behind effective pallet flow roller track design involve specialized considerations addressing the unique challenges of pallet movement:

- Enhanced load capacity accommodating full pallet weights (typically 1,000-2,500kg)

- Reinforced frames withstanding the structural forces of dynamic pallet storage

- Precision flow control preventing excessive speed development

- Speed controllers regulating descent on steeper inclines

- Entry guides facilitating proper pallet alignment during loading

- Specialized rollers accommodating pallet irregularities

- Separators preventing pallet-to-pallet contact and pressure

These engineering features deliver significant operational advantages in high-volume warehouse environments:

- Increased storage density with up to 60% more pallets versus selective racking

- Automatic FIFO inventory rotation ensuring proper stock management

- Reduced forklift travel distances and operating time

- Separate loading and unloading aisles preventing workflow conflicts

- Enhanced inventory organization with dedicated product lanes

- Improved workplace safety with reduced aisle congestion

- Simplified inventory management with visual stock level indication

Typical applications particularly suited to pallet flow roller tracks include:

- High-volume distribution centres optimizing space utilization

- Food and beverage operations requiring strict FIFO rotation

- Manufacturing facilities with significant finished goods storage

- Cold storage environments maximizing expensive refrigerated space

- Cross-docking operations requiring temporary dynamic storage

- Staging areas between production and shipping functions

- High-throughput order fulfilment operations

Our pallet flow roller track systems can be implemented as standalone solutions or integrated within larger storage systems including selective racking, push-back racking, or custom configurations. Available in standard and custom dimensions, these systems accommodate various pallet sizes and operational requirements while maintaining consistent performance characteristics.

Hall-Fast's technical specialists can develop customized pallet flow solutions addressing your specific operational challenges, from initial concept through detailed design to implementation support. Our comprehensive approach ensures you receive pallet flow roller track systems optimized for your unique requirements, delivering maximum efficiency and long-term value for your material handling investment.

Contact us via sales@hall-fast.com or online online now https://www.hall-fast.com/industrial-commercial-equipment/storage-shelving/roller-tracks