Quarter-turn fasteners or ¼ turn fasteners are quick-release mechanical fasteners commonly used to secure panels, covers, or components that require frequent access. They are designed to lock and unlock with a simple 90-degree (quarter-turn) rotation, making them ideal for applications where quick and easy fastening is essential. Here’s an overview of their types, applications, materials, and advantages:

Take a look at Hall-Fast’s range https://www.hall-fast.com/fasteners-small-components/quarter-turn-fasteners-locks

Types of Quarter-Turn Fasteners

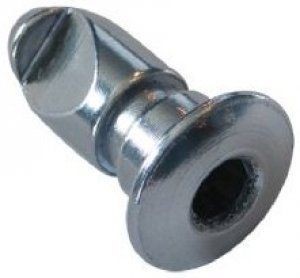

- Slotted Head: Operated with a flat-head screwdriver, often used in applications where tool-assisted fastening is preferred.

- Winged Head: Designed for tool-less operation, often seen in panels or compartments that need frequent access by hand.

- Flush Head: These fasteners sit flush with the surface of the panel, reducing aerodynamic drag and providing a clean, smooth appearance, often used in aerospace and automotive applications.

- Button Head: Raised, smooth head for easy turning by hand or with a tool, used where aesthetics and ease of access are important.

-Dzus Fasteners: A common type of quarter-turn fastener that uses a spring-loaded mechanism for quick fastening, popular in racing and aviation for securing body panels.

Materials

- Stainless Steel: Durable and corrosion-resistant, ideal for outdoor or marine environments where rust could be an issue.

- Aluminium: Lightweight and resistant to corrosion, commonly used in aerospace, automotive, and electronics industries.

- Carbon Steel: Strong and durable, often used in heavy-duty applications. May be zinc-plated for corrosion resistance.

- Plastic: Lightweight and non-corrosive, used in lighter-duty applications like electronics, where metal fasteners might be too heavy or conductive.

Applications of Quarter-Turn Fasteners

- Aerospace and Aviation: Widely used to secure access panels, fairings, or hatches on airplanes and helicopters. These fasteners allow for quick inspections or repairs without the need for tools.

- Automotive and Motorsports: Often used to secure body panels, hoods, or race car components. Dzus fasteners are especially popular in motorsports for their speed and ease of use during pit stops.

- Industrial Equipment: Used to fasten machine covers, control panels, or access doors in factories and manufacturing environments.

- Electronics: Securing housings, access panels, or internal components in electronic devices or enclosures.

- Marine: Used in boat-building or marine equipment, where exposure to saltwater and harsh conditions requires corrosion-resistant fasteners.

- HVAC Systems: Fasteners are often used to secure access panels for air handling units or ventilation systems where regular maintenance is needed.

- Military and Defence: Used in military vehicles and equipment for rapid assembly and disassembly in the field.

Advantages of Quarter-Turn Fasteners

- Quick Operation: Only a 90-degree turn is needed to lock or unlock the fastener, allowing for rapid panel or component removal.

- Tool-Free or Minimal Tool Operation**: Many designs allow for hand operation or use of simple tools, increasing convenience during maintenance or adjustments.

- Secure Hold: Despite their ease of use, quarter-turn fasteners provide a tight, secure hold that resists vibration or loosening.

- Durability: Made from materials like stainless steel or aluminium, they can withstand harsh environments, frequent use, and exposure to the elements.