In today's competitive logistics and warehousing environment, operational versatility and efficiency are crucial for maintaining competitive advantage. Telescopic fork extensions have emerged as innovative attachments that significantly enhance the capabilities of standard forklifts, enabling them to handle oversized, long, or awkwardly shaped loads with greater flexibility than conventional fixed extensions. This comprehensive guide explores how these adjustable attachments can revolutionize material handling operations across multiple industries.

Understanding Telescopic Fork Extension Technology

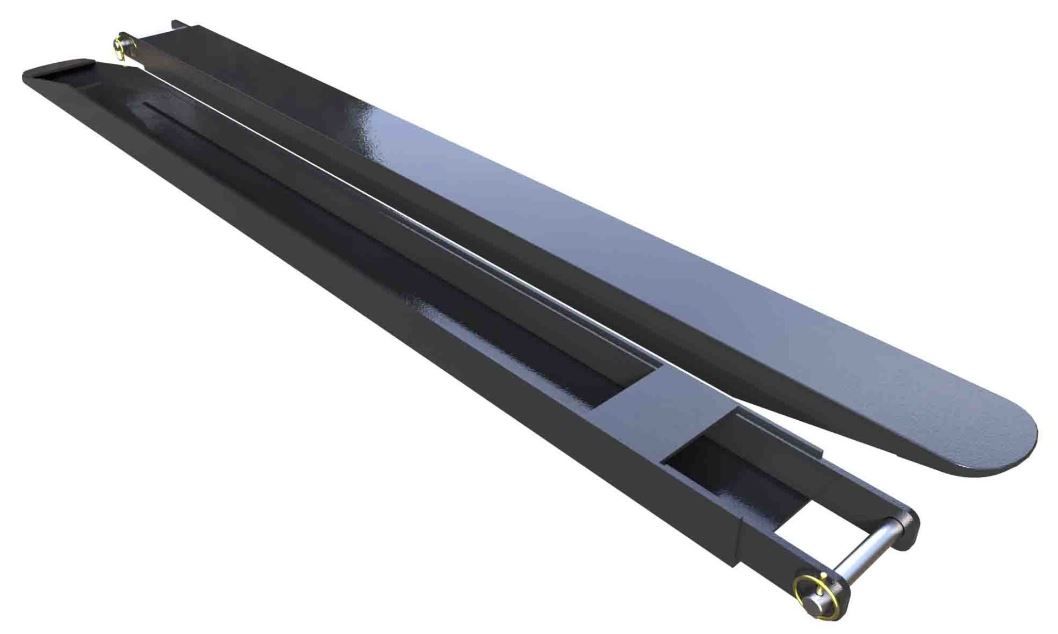

Telescopic fork extensions represent an advanced evolution of standard fork extensions, incorporating adjustable length capabilities that provide unprecedented flexibility for diverse material handling requirements. Unlike fixed extensions that offer only a single length option, telescopic designs feature:

Mechanical Design

- Nested sections that slide within each other for length adjustment

- Locking mechanisms to secure extended positions

- Reinforced structures to maintain capacity at extension

- Wear pads or rollers to facilitate smooth adjustment

- End stops to prevent over-extension

Structural Characteristics

- High-strength steel construction for durability

- Precision engineering for proper fit on forklift tines

- Tapered profiles for easier load entry

- Reinforced heel sections for maximum strength

- Chamfered tips to reduce product damage risk

Adjustment Mechanisms

- Manual adjustment systems with secure locking

- Hydraulic extension systems for remote operation

- Pin-lock positioning for multiple preset lengths

- Incremental adjustment capabilities

- Visual indicators for extension position

This sophisticated design enables a single set of extensions to replace multiple fixed-length extensions, providing adaptability for varying load types while reducing equipment investment and storage requirements.

Operational Advantages Across Industries

The implementation of telescopic fork extensions delivers significant operational improvements across diverse sectors:

Warehousing and Distribution

Modern distribution centres handle increasingly diverse product dimensions. Telescopic extensions transform handling capabilities:

Flexible Load Accommodation

- Adapt to varying pallet sizes from Euro to oversize

- Handle non-standard shipping platforms efficiently

- Support odd-length items without dedicated equipment

- Enable safe transport of long materials

- Adjust to mixed load requirements on demand

Space Optimization

- Access deep-reach storage positions

- Enable double-deep racking utilization

- Support block stacking of varying dimensions

- Facilitate efficient trailer loading with mixed products

- Optimize handling in narrow aisle environments

Distribution centres implementing telescopic extensions report significant improvements in handling flexibility and throughput for non-standard loads, with corresponding reductions in equipment requirements and handling damage.

Manufacturing and Production

Manufacturing operations process materials with diverse dimensions throughout production cycles. Telescopic extensions provide critical advantages:

Production Versatility

- Handle raw materials of varying lengths

- Support finished products with different dimensions

- Adapt to changing production requirements

- Enable efficient machine loading/unloading

- Facilitate mold or die handling of different sizes

Process Integration

- Allow single-equipment handling throughout processes

- Support just-in-time material delivery

- Adapt to multiple production line requirements

- Enable efficient machine setup and changeover

- Facilitate varying staging area configurations

Manufacturing facilities report significant improvements in material flow and reduced equipment needs after implementing telescopic fork extensions for handling variable-dimension materials.

Construction and Building Materials

Construction materials present some of the most challenging dimensional variations in material handling. Telescopic extensions transform these operations:

Material Adaptability

- Handle lumber packages of varying lengths

- Support efficient drywall and panel material movement

- Adapt to pipe and structural steel dimensions

- Enable safe transport of engineered components

- Facilitate efficient handling of diverse building materials

Site Logistics

- Support efficient offloading of mixed deliveries

- Enable precise placement in constrained site areas

- Adapt to varying storage arrangements as construction progresses

- Facilitate material staging for different work phases

- Support efficient vehicle loading for site moves

Construction operations utilizing telescopic extensions report significant improvements in material handling efficiency and reduced equipment needs for managing diverse building materials.

Key Operational Benefits

Beyond industry-specific advantages, telescopic fork extensions deliver broad operational improvements:

Equipment Fleet Optimization

- Reduce the number of dedicated handling devices

- Decrease attachment inventory requirements

- Lower investment in specialized equipment

- Minimize storage space for attachments

- Simplify equipment management

Enhanced Safety Performance

- Provide appropriate support length for varying loads

- Reduce improvisation with inadequate equipment

- Ensure proper load support throughout transport

- Minimize the risk of load shifts or drops

- Decrease the need for manual load stabilization

Improved Operational Efficiency

- Reduce attachment change time between different loads

- Decrease equipment repositioning requirements

- Enable rapid adaptation to changing handling needs

- Minimize operator decision complexity

- Support efficient mixed-load handling

Cost Reduction Opportunities

- Lower capital investment in multiple extensions

- Reduce product damage from improper support

- Decrease equipment maintenance costs

- Minimize operator time for attachment changes

- Optimize storage space utilization

Organizations implementing telescopic extensions typically report equipment cost reductions of 30-50% compared to maintaining multiple fixed-length extension sets, with corresponding improvements in operational flexibility.

Advanced Features and Innovations

The market offers several advanced features in telescopic fork extensions that provide additional operational benefits:

Length Indication Systems

- Visual indicators showing current extension position

- Measurement markings for precise adjustment

- Digital readouts on hydraulic systems

- Position memory for common settings

- Automatic length recording for documentation

Enhanced Visibility Features

- High-visibility finishes for better operator awareness

- Integrated fork tip markers for accurate positioning

- Reflective elements for low-light environments

- Profile designs that minimize sight obstruction

- Contrast colouring for extension position awareness

Material and Construction Innovations

- Composite materials for weight reduction

- Wear-resistant surfaces for extended service life

- Corrosion-resistant finishes for harsh environments

- Optimized profiles for maximum strength-to-weight ratio

- Specialized surfaces for different load types

Adjustment Mechanism Advancements

- Quick-release systems for rapid length changes

- Tool-free adjustment capabilities

- Hydraulic extension systems with proportional control

- Remote adjustment from operator position

- Position memory and return functionality

These advanced features further enhance the operational benefits of telescopic extensions, providing additional safety, efficiency, and ease of use.

Selection Considerations for Maximum Benefit

Choosing appropriate telescopic fork extensions requires systematic evaluation of operational requirements:

Load Analysis

- Dimensional range of typical and maximum loads

- Weight distribution patterns across length

- Material characteristics affecting support requirements

- Surface conditions affecting friction and stability

- Special handling considerations for sensitive loads

Operational Requirements

- Extension range needed for various applications

- Frequency of length adjustment

- Environmental conditions affecting operation

- Storage constraints for extensions when not in use

- Compatibility with existing handling procedures

Equipment Compatibility

- Forklift specifications and load capacity

- Fork dimensions and carriage class

- Hydraulic capabilities if using powered extensions

- Visibility considerations with extensions installed

- Stability impacts at various extension lengths

Safety and Performance Factors

- Load capacity ratings at different extensions

- Deflection characteristics under load

- Securing mechanism reliability

- Visual indicators for proper installation

- Wear indicators for maintenance timing

This comprehensive evaluation ensures selected extensions deliver maximum operational benefit while maintaining safety compliance and equipment compatibility.

Implementation Best Practices

Successfully implementing telescopic fork extensions requires attention to operational details:

- Comprehensive Training Program Develop specific training covering:

- Extension selection for different load types

- Proper installation and securing techniques

- Safe operation with extended loads

- Length adjustment procedures and verification

- Capacity limitations at different extensions

- Operational Protocol Development Establish documented procedures for:

- Pre-use inspection requirements

- Length selection guidelines for different loads

- Movement safety considerations with extended loads

- Storage and maintenance protocols

- Capacity calculation based on extension length

- Integration with Existing Processes Modify workflows to leverage new capabilities:

- Receiving and shipping procedures

- Storage layout optimization

- Production material flow

- Load building practices

- Equipment allocation and scheduling

- Performance Monitoring System Implement ongoing evaluation:

- Handling efficiency metrics

- Extension utilization patterns

- Maintenance requirement tracking

- Operator feedback collection

- Continuous improvement identification

- Maintenance Program Implementation Establish systematic maintenance protocols:

- Regular inspection schedules

- Wear component assessment

- Adjustment mechanism maintenance

- Structural integrity verification

- Documentation of all maintenance activities

Understanding Load Capacity Implications

One of the most critical aspects of telescopic fork extensions is their impact on forklift load capacity. As extensions increase in length, load capacity decreases according to basic leverage principles. Operators must understand:

Load Centre Distance Effects When fork length increases, the load centre distance extends, reducing effective capacity:

- Standard 1200mm forks typically have a 600mm load centre

- Extended to 1800mm, the load centre becomes 900mm

- Extended to 2400mm, the load centre reaches 1200mm

Each extension increment reduces capacity proportionally, often following this approximate pattern:

- 25% extension = 20% capacity reduction

- 50% extension = 33% capacity reduction

- 100% extension = 50% capacity reduction

Weight Distribution Considerations Load weight distribution becomes increasingly critical with extensions:

- Uneven weight distribution can create dangerous leverage

- Front-weighted loads significantly increase tip-over risk

- Side-centered placement is essential for stability

- Load shifting during transport creates additional hazards

Dynamic Forces Movement creates additional forces that further affect capacity:

- Acceleration and deceleration increase effective load momentum

- Turning introduces side forces that reduce stability

- Traveling over uneven surfaces creates vertical forces

- Sudden stops magnify forward moment

Comprehensive training must emphasize these physics principles to ensure safe operation with telescopic extensions.

Sourcing Quality Telescopic Fork Extensions

When investing in telescopic fork extensions, partnering with established suppliers ensures both product quality and appropriate application matching. Hall-Fast offers an extensive range of telescopic fork extensions designed to enhance operational capabilities while maintaining strict safety standards.

Their comprehensive selection includes various configurations to address different length requirements, load capacities, and operational environments, all manufactured to meet or exceed relevant safety standards. For operations with unique requirements, custom-engineered solutions can be developed to address specific challenges.

For expert guidance on selecting the optimal telescopic fork extensions for your specific operational needs, contact the Hall-Fast team directly at sales@hall-fast.com. Their specialists can assist in evaluating your requirements and recommending appropriate solutions that balance flexibility, safety, and value.

Conclusion

Telescopic fork extensions represent a transformative investment for operations handling loads with varying dimensions. By implementing these versatile attachments with proper training and protocols, organizations can significantly enhance handling capabilities, improve operational flexibility, and reduce equipment investment requirements.

With careful selection, implementation, and ongoing management, these adaptable extensions deliver substantial benefits across diverse industries and applications. Whether handling building materials, oversized components, or non-standard pallets, telescopic fork extensions provide the adjustability, safety, and efficiency necessary for optimal material handling operations.