Industrial-Grade Heavy Duty Roller Tracks for Pallets: Robust Material Flow Solutions

Pallet handling operations present unique material flow challenges, requiring specialized heavy duty roller tracks designed specifically for the substantial weights, dimensional variations, and operational intensity common in industrial pallet movement. These robust systems provide the foundation for efficient pallet flow, supporting FIFO (First-In, First-Out) inventory management while maximizing storage density in high-volume warehouse environments.

Hall-Fast supplies premium heavy duty roller tracks engineered specifically for pallet applications in distribution, manufacturing, and logistics operations. Our industrial-grade systems incorporate enhanced structural components and specialized flow control features, delivering reliable pallet movement while ensuring long-term performance under demanding conditions.

Specialized Engineering for Pallet Applications

Quality heavy duty roller tracks for pallets incorporate multiple specialized design elements addressing the unique challenges of pallet handling:

Enhanced Structural Components:

- Reinforced frame rails withstanding dynamic pallet loads

- Heavy-gauge materials preventing deformation under continuous use

- Precision-engineered connections maintaining alignment under stress

- Structural bracing providing additional support at critical points

- Industrial-grade fasteners preventing loosening under vibration

- Reinforced mounting points distributing load to support structures

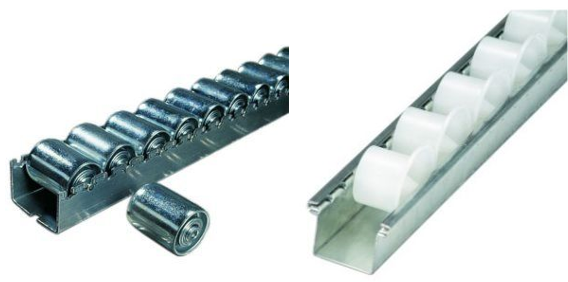

Specialized Roller Design:

- Larger diameter rollers supporting distributed pallet weight

- Heavy-duty bearings ensuring long-term operational reliability

- Full-width rollers accommodating variable pallet conditions

- Impact-resistant materials withstanding forklift loading forces

- Optimal spacing preventing pallet slat interference

- Enhanced surface durability resisting damage from pallet contact

Critical Flow Control Features:

- Entry guide rails ensuring proper pallet alignment during loading

- Speed controllers preventing excessive velocity development

- Braking systems regulating descent on steeper inclines

- Ramp sections creating controlled transitions between levels

- Pallet separators preventing pressure accumulation in lanes

- Exit controllers ensuring safe pallet presentation for retrieval

Safety and Operational Enhancements:

- Load capacity indicators providing clear operational guidelines

- Visual markers indicating proper loading positions

- Safety stops preventing accidental pallet discharge

- Impact zones absorbing energy at critical transition points

- Enhanced guarding protecting operators during loading/unloading

- Inspection access facilitating regular maintenance

Performance Specifications and Selection Guidance

When selecting heavy duty roller tracks for pallet applications, these specifications should be evaluated against your specific operational requirements:

Load Capacity Considerations:

- Standard pallet loads (500-1000kg): Medium-duty pallet tracks

- Heavy pallet loads (1000-1500kg): Heavy-duty industrial tracks

- Extra-heavy applications (1500kg+): Reinforced industrial tracks with enhanced support

- Dynamic loading situations: Systems with additional safety factor ratings

- Uneven weight distribution: Full-width roller designs with additional supports

- Shock loading conditions: Impact-resistant systems with reinforced connections

Pallet Type Compatibility:

- Standard GMA pallets (1200x1000mm): Universal pallet tracks

- Euro pallets (1200x800mm): European specification tracks

- Block pallets: Full-width roller designs preventing block interference

- Stringer pallets: Standard roller spacing with adequate support

- Plastic pallets: Systems with appropriate friction characteristics

- Non-standard dimensions: Custom width configurations available

Operational Intensity Factors:

- High-throughput environments: Enhanced durability components

- 24/7 operations: Industrial-grade bearings and reduced maintenance designs

- Frequent loading/unloading: Reinforced entry and exit sections

- Seasonal intensity variations: Systems with appropriate operational margins

- Multiple forklift operators: Enhanced guiding features for varied loading styles

- Challenging environmental conditions: Materials selected for specific exposures

Application-Specific Solutions

Hall-Fast offers specialized heavy duty roller track configurations optimized for specific pallet handling environments:

Distribution Centre Pallet Flow: Our DC-Pro Pallet Track system delivers exceptional performance in high-throughput distribution environments:

- Robust construction withstanding intensive multi-shift operations

- Enhanced entry guides accommodating varied forklift loading approaches

- Advanced speed control preventing pallet damage during movement

- Full-width roller design supporting multiple pallet types

- Optimized incline calculations balancing flow and control

- Modular design allowing configuration to specific facility requirements

Manufacturing Buffer Storage: For production environment pallet staging, our Manufacturing Buffer system offers advantages including:

- Simplified loading interface for production equipment integration

- FIFO flow ensuring proper production sequence maintenance

- Visual inventory management supporting lean methodologies

- Durable construction withstanding industrial environments

- Customizable dimensions matching production requirements

- Reinforced design tolerating manufacturing equipment contact

Cold Storage Applications: Our specialized Cold Storage Pallet Track system addresses the unique challenges of refrigerated environments:

- Materials selected for low-temperature performance

- Enhanced corrosion resistance withstanding humid conditions

- Special lubricants maintaining performance at low temperatures

- Reduced maintenance design minimizing work in cold environments

- Increased safety factors accommodating cold-stiffened pallets

- Specialized finishes preventing ice accumulation on critical components

High-Density Storage Systems: For maximum cubic utilization, our High-Density Pallet Flow system provides:

- Deep-lane capability supporting 20+ pallet positions

- Enhanced speed control for longer lane applications

- Intermediate supports for extended lane configurations

- Advanced braking systems preventing excessive speed development

- Specialized pallet separators preventing pressure accumulation

- Entry/exit transitions designed for deep-lane operation

Hall-Fast's technical specialists can evaluate your specific pallet handling requirements and recommend the optimal heavy duty roller track configuration for your operation. Our comprehensive approach includes load analysis, workflow evaluation, and system design, ensuring you receive pallet flow solutions that deliver exceptional performance and long-term value for your material handling investment.

Contact us via sales@hall-fast.com or online online now https://www.hall-fast.com/industrial-commercial-equipment/storage-shelving/roller-tracks