Hall-Fast, based in Mansfield, Nottinghamshire, offers a comprehensive range of A-Raymond plastic cable clips engineered for efficient, cost-effective wire management across automotive, industrial, and commercial applications. As an authorised UK distributor of A-Raymond fastening solutions, Hall-Fast provides immediate access to precision-moulded plastic cable clips that deliver excellent corrosion resistance, electrical insulation, and lightweight performance while maintaining superior retention characteristics for diverse cable management requirements.

Professional Plastic Cable Clips for Cost-Effective Applications

A-Raymond plastic cable clips represent advanced polymer technology specifically engineered for applications requiring lightweight, corrosion-resistant wire management solutions. These precision-manufactured plastic components combine superior material properties with innovative design features to deliver reliable cable securing performance while offering significant cost advantages over metal alternatives for applications where extreme mechanical strength is not required.

The comprehensive plastic cable clip portfolio encompasses single tube clips for individual cable management, double and triple tube clips for multiple cable routing, edge mount clips for panel edge applications, plug mount clips for through-hole installations, stud mount clips for threaded applications, and adhesive mount clips for surface mounting scenarios. Each clip variant utilizes advanced thermoplastic materials that provide consistent performance across standard environmental conditions while maintaining easy installation characteristics.

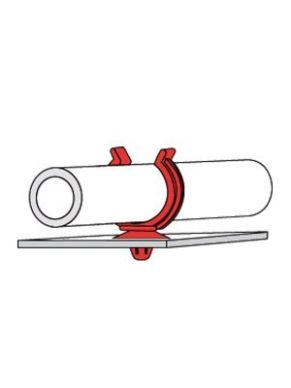

Single Tube Plastic Cable Clips for Individual Cable Management

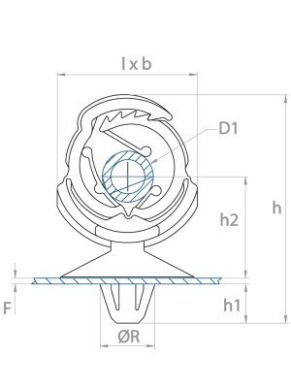

A-Raymond single tube plastic cable clips provide efficient solutions for individual cable routing applications where lightweight, cost-effective fastening is required. These precision-moulded clips feature optimized cable retention areas designed to secure individual cables, wires, or small tubes while maintaining easy installation and removal characteristics for maintenance and reconfiguration operations.

The single tube design incorporates carefully engineered retention mechanisms that provide secure cable holding without over-compression that could damage cable sheathing or compromise electrical performance. Various tube diameter compatibilities accommodate standard cable sizes commonly encountered in automotive wiring harnesses, industrial control systems, and commercial equipment installations.

Thermoplastic construction provides excellent electrical insulation properties essential for electrical applications while offering superior corrosion resistance compared to metal alternatives. The lightweight design minimizes added weight in weight-sensitive applications while providing reliable retention under normal service conditions.

Installation characteristics enable rapid deployment using simple push-in or snap-on methods that require no specialized tools or complex procedures. The plastic material properties maintain consistent retention force across standard temperature ranges while providing enhanced resistance to environmental chemicals and cleaning agents commonly encountered in service environments.

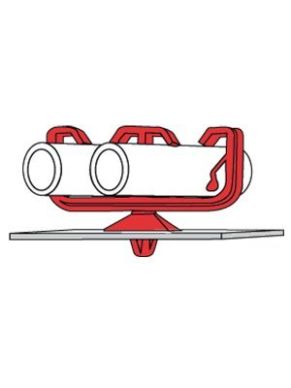

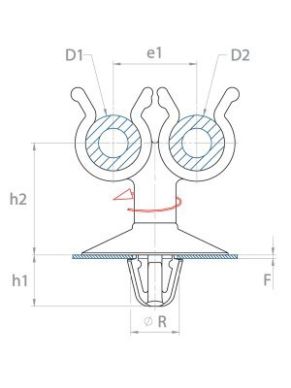

Double and Triple Tube Plastic Cable Clips for Multiple Cable Routing

A-Raymond double and triple tube plastic cable clips are specifically designed for applications requiring multiple cable routing within single mounting points, providing efficient space utilization while maintaining organized cable management. These advanced plastic clips feature multiple cable retention areas that accommodate various cable combinations while ensuring proper separation and strain relief.

The double tube configuration provides optimal solutions for applications requiring paired cable routing such as power and signal cable combinations commonly found in automotive and industrial equipment. The design maintains proper cable separation while providing unified mounting that simplifies installation and reduces hardware requirements.

Triple tube variants accommodate more complex cable routing scenarios where multiple cables must be managed within confined spaces. The design ensures adequate cable separation while maintaining compact overall dimensions that minimize space requirements in densely packed installations.

Swivel system capabilities enable optimal cable orientation relative to mounting surfaces while maintaining secure retention. The modular design allows connection of multiple clips to create complex routing networks that accommodate evolving cable management requirements and maintenance accessibility needs.

Advanced thermoplastic formulations provide enhanced environmental resistance for outdoor applications and chemically aggressive environments. Specialized material options include UV-stabilized compounds for extended outdoor service life and flame-retardant formulations for electrical safety applications.

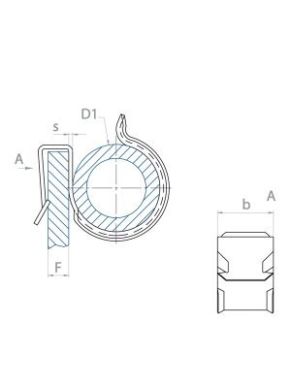

Edge Mount Plastic Cable Clips with Integrated Spring Steel

A-Raymond edge mount plastic cable clips feature innovative hybrid construction that combines thermoplastic housings with integrated spring steel retention elements, providing enhanced performance and retention characteristics while maintaining the cost and weight advantages of plastic construction. These advanced clips attach to panel edges without requiring pre-drilled holes or secondary fastening hardware.

The integrated spring steel elements provide superior retention force compared to all-plastic designs while maintaining the corrosion resistance and electrical insulation properties of thermoplastic construction. The hybrid approach optimizes performance characteristics while maintaining cost-effective manufacturing compatibility.

Various cable capacity configurations accommodate applications ranging from single wire management through larger bundle routing requirements. The edge mounting capability eliminates panel modification requirements while providing secure attachment that resists vibration-induced loosening under normal service conditions.

Barbed retention mechanisms ensure positive panel engagement while maintaining easy installation characteristics that enable rapid deployment during production assembly operations. The design accommodates various panel thickness ranges commonly encountered in automotive interior assemblies and industrial equipment housings.

Tool-free installation methods minimize labour requirements while ensuring consistent retention characteristics across production volumes. Quality installation guidelines ensure optimal performance while maintaining serviceability for maintenance and reconfiguration requirements.

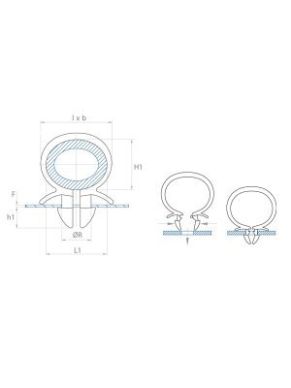

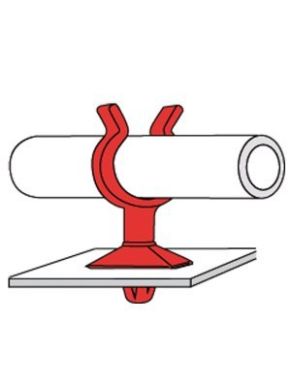

Plug Mount Plastic Cable Clips for Through-Hole Applications

A-Raymond plug mount plastic cable clips provide versatile solutions for through-hole panel mounting applications where robust cable retention is required. These precision-moulded clips feature dart-style or expandable retention mechanisms designed for secure panel attachment through simple push-through installation procedures.

The plug mount design accommodates various hole diameter specifications commonly found in automotive and industrial panels while providing excellent pull-out resistance under mechanical stress. Different anchoring systems are available to accommodate various hole depths and panel thickness requirements.

Single and multiple tube variants address diverse cable management requirements from individual wire routing through larger bundle applications. Swivel system options enable optimal cable orientation for complex routing scenarios while maintaining secure panel attachment.

Advanced dart configurations provide self-expanding retention that engages panel holes with sufficient force to resist displacement under vibration and mechanical stress. The plastic construction provides electrical insulation while maintaining resistance to environmental contamination and chemical exposure.

Installation requires simple push-through operation that can be performed manually without specialized tools, enabling rapid deployment during assembly operations while maintaining consistent retention characteristics. Various design modifications accommodate specific mounting requirements and environmental constraints.

Stud Mount Plastic Cable Clips for Threaded Applications

A-Raymond stud mount plastic cable clips integrate cable retention functionality with threaded stud attachment capability, providing efficient solutions for applications where stud mounting points are available or preferred. These clips feature female threading or snap-on mechanisms designed for secure attachment to metric studs.

The stud mounting configuration provides enhanced security for cable routing applications while eliminating the need for separate mounting hardware. Various stud diameter compatibilities accommodate standard threading specifications commonly encountered in automotive and industrial applications.

Single and double tube configurations address diverse bundling requirements while maintaining compact designs that minimize space requirements. The plastic construction provides electrical insulation properties essential for electrical applications while offering corrosion resistance advantages over metal alternatives.

Push-on installation characteristics enable rapid attachment to studs without requiring tools or complex procedures. The design maintains secure retention under vibration while providing easy removal for maintenance and reconfiguration operations.

Advanced thermoplastic materials ensure consistent performance across standard temperature ranges while providing resistance to automotive fluids and industrial chemicals commonly encountered in service environments. Specialized formulations address specific environmental requirements including enhanced chemical resistance and temperature stability.

Adhesive Mount Plastic Cable Clips for Surface Applications

A-Raymond adhesive mount plastic cable clips provide flexible cable management solutions for applications where mechanical fastening is impractical or surface modification must be avoided. These clips incorporate high-performance adhesive systems that create reliable mounting points on various surface materials including metal, plastic, and composite panels.

The adhesive mount design enables installation on flat panel surfaces without requiring holes, studs, or other mounting hardware. Pre-assembled adhesive systems eliminate field preparation requirements while ensuring consistent bond strength and long-term reliability.

Multiple tube configurations accommodate various cable bundling requirements while maintaining low-profile designs that minimize space requirements. The lightweight plastic construction provides optimal weight distribution for adhesive mounting applications.

Temperature-resistant adhesive formulations maintain bond integrity across standard automotive and industrial temperature ranges while providing enhanced resistance to environmental exposure. Surface preparation guidelines ensure optimal adhesive performance while addressing various substrate materials and environmental conditions.

Installation procedures require simple surface cleaning followed by protective film removal and clip positioning. Quality installation practices ensure reliable long-term performance while maintaining removability for planned maintenance operations.

Advanced Thermoplastic Material Specifications

A-Raymond plastic cable clips utilize advanced thermoplastic formulations specifically engineered for demanding cable management applications. Material options include nylon, acetal, polyethylene, polypropylene, and ABS compounds selected for specific performance requirements and environmental conditions.

High-quality nylon formulations provide excellent mechanical strength, temperature stability, and chemical resistance while maintaining consistent dimensional stability across service temperature ranges. Acetal variants offer enhanced fatigue resistance and precision moulding capabilities for applications requiring tight tolerances.

Polyethylene and polypropylene options provide superior chemical resistance and environmental durability for outdoor applications and chemically aggressive environments. ABS formulations offer enhanced impact resistance and surface finish quality for visible applications requiring aesthetic considerations.

UV-stabilized compounds prevent degradation under extended sunlight exposure, making these clips suitable for outdoor installations and automotive exterior applications. Flame-retardant formulations meet electrical safety requirements for applications in electrical enclosures and electronic equipment.

Color options include natural, black, and grey as standard offerings, with custom colours available for specific applications requiring visual identification or aesthetic matching. Material selection guidelines ensure appropriate clip specification for specific environmental and performance requirements.

Electrical Insulation and Safety Characteristics

A-Raymond plastic cable clips provide excellent electrical insulation properties essential for electrical and electronic applications where metal clips could create unwanted electrical connections or safety hazards. The thermoplastic construction eliminates concerns about electrical conductivity while providing reliable cable retention.

Dielectric strength characteristics meet industry standards for electrical insulation applications while maintaining consistent properties across temperature ranges and environmental conditions. The insulating properties prevent galvanic corrosion in applications where dissimilar metals could create electrochemical reactions.

Flame-retardant formulations provide enhanced safety characteristics for electrical applications requiring compliance with fire safety standards. Testing protocols verify flame propagation resistance while ensuring that combustion products do not compromise electrical safety.

Chemical resistance properties ensure compatibility with electrical cleaning solvents and maintenance chemicals commonly used in electrical equipment servicing. The plastic construction resists degradation from electrical field exposure and environmental contaminants that could compromise insulation properties.

Quality assurance procedures verify electrical insulation characteristics throughout manufacturing processes while ensuring consistent material properties across production volumes. Documentation supports electrical safety compliance and regulatory approval processes.

Environmental Performance and Durability

A-Raymond plastic cable clips are engineered to provide reliable performance across diverse environmental conditions commonly encountered in automotive, industrial, and commercial applications. Material formulations address specific environmental challenges including temperature cycling, chemical exposure, and UV radiation.

Temperature performance specifications accommodate standard automotive and industrial operating ranges while maintaining consistent retention characteristics and dimensional stability. Low-temperature flexibility ensures reliable performance in cold climate applications while high-temperature stability maintains mechanical properties under elevated operating conditions.

Chemical resistance properties provide compatibility with automotive fluids, industrial solvents, cleaning agents, and environmental contaminants. Specialized formulations offer enhanced resistance to specific chemicals for applications requiring extended exposure to aggressive environments.

UV stabilization prevents material degradation under extended sunlight exposure while maintaining mechanical properties and surface finish quality. Outdoor durability testing verifies long-term performance under representative environmental conditions including temperature cycling and moisture exposure.

Corrosion resistance advantages over metal alternatives eliminate concerns about rust and oxidation while maintaining consistent appearance and performance throughout service life. The plastic construction resists contamination buildup that could compromise retention or appearance characteristics.

Custom Plastic Cable Clip Solutions and Engineering Support

A-Raymond engineering capabilities enable development of custom plastic cable clip solutions for specialized applications requiring unique mounting configurations, enhanced environmental protection, or specific performance characteristics. Custom development addresses unique cable routing requirements and application-specific environmental challenges.

Advanced injection moulding capabilities accommodate complex geometries and specialized material requirements while maintaining cost-effective manufacturing compatibility. Overholding and bi-injection processes enable integration of multiple materials within single components for enhanced performance characteristics.

Material selection expertise ensures optimal thermoplastic specification for demanding applications while considering factors such as environmental exposure, mechanical requirements, electrical properties, and regulatory compliance needs. Custom formulations address specialized performance requirements not available in standard material offerings.

Prototype development services enable application validation and performance verification before production implementation. Testing capabilities include retention force verification, environmental exposure assessment, and electrical property evaluation under representative service conditions.

Technical consultation services assist customers in selecting appropriate plastic cable clip configurations while addressing specific application requirements and constraints. Engineering support ensures optimal performance while minimizing total cost of ownership across product lifecycles.

Quality Standards and Manufacturing Excellence

A-Raymond plastic cable clips are manufactured to demanding quality standards in facilities equipped with advanced injection moulding equipment and comprehensive quality control systems. Manufacturing processes incorporate precision moulding techniques and material verification procedures that ensure consistent product quality and performance reliability.

Quality assurance protocols include dimensional verification, material property testing, and retention force validation to ensure compliance with engineering specifications. Environmental testing verifies performance characteristics under representative service conditions including temperature cycling and chemical exposure assessment.

Statistical process control procedures monitor manufacturing consistency while identifying potential quality issues before product shipment. Continuous improvement initiatives incorporate customer feedback and field performance data to enhance product design and manufacturing processes.

Industry certifications and compliance with automotive and industrial standards ensure that A-Raymond plastic cable clips meet performance requirements for demanding applications. Comprehensive documentation supports specification processes while providing verification of performance characteristics for quality management systems.

Technical Support and Application Assistance

Hall-Fast provides comprehensive technical support services for A-Raymond plastic cable clip selection, application engineering, and performance optimization. Technical consultation includes cable management system design, material selection, installation guidance, and troubleshooting support for challenging applications.

Application assistance addresses unique cable routing challenges, environmental considerations, and cost optimization opportunities. Technical support services ensure optimal clip selection while addressing specific application requirements and constraints that may impact performance or installation procedures.

For technical assistance with A-Raymond plastic cable clip selection or to discuss specific wire management requirements, customers can contact Hall-Fast's experienced technical support team. Additionally, Hall-Fast offers access to numerous other leading fastener brands through their comprehensive supplier network, ensuring customers receive optimal solutions for all cable management applications.

The extensive A-Raymond plastic cable clip portfolio available through Hall-Fast provides cost-effective, reliable solutions for diverse wire management challenges across automotive, industrial, and commercial applications. Free delivery is available on orders over £54.99 to UK mainland destinations, with next-day delivery options available for many standard products to support urgent project requirements and maintenance operations.

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price

-

Call For Price