Hall-Fast, based in Mansfield, Nottinghamshire, offers a comprehensive range of A-Raymond metal cable clips engineered for demanding industrial, automotive, and commercial wire management applications. As an authorised UK distributor of A-Raymond fastening solutions, Hall-Fast provides immediate access to precision-manufactured spring steel cable clips that deliver superior retention force, vibration resistance, and long-term durability in challenging environmental conditions where plastic alternatives prove inadequate.

Professional Spring Steel Cable Clips for Demanding Applications

A-Raymond metal cable clips represent advanced wire management technology specifically engineered for applications requiring enhanced mechanical strength, temperature resistance, and vibration immunity. These precision-manufactured spring steel components combine superior material properties with innovative design features to deliver reliable cable securing performance in automotive underhood environments, industrial machinery installations, and high-stress applications where standard plastic clips cannot provide adequate retention.

The comprehensive metal cable clip portfolio encompasses edge mounting designs for panel edge applications, plug mounting configurations for through-hole installations, dart-style retention mechanisms for blind mounting scenarios, and heel-toe mounting systems that provide exceptional retention force in high-vibration environments. Each clip variant utilizes high-grade spring steel construction that maintains consistent clamping force across extreme temperature ranges while resisting fatigue failure under repeated mechanical stress.

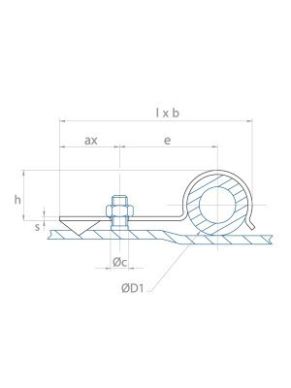

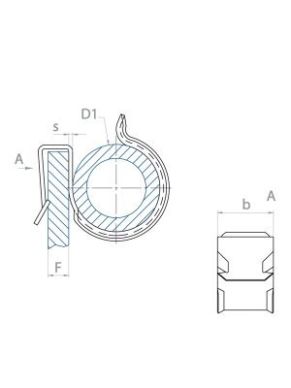

Edge Mount Metal Cable Clips with Barb Retention Systems

A-Raymond edge mount metal cable clips provide robust wire management solutions for panel edge applications where drilling or panel modification is impractical or undesirable. These spring steel clips feature precision-formed barb configurations that ensure secure panel attachment while maintaining easy installation characteristics that enable rapid deployment during production assembly operations.

The edge mounting design incorporates self-retaining mechanisms that eliminate the need for secondary fastening hardware while providing superior retention force compared to plastic alternatives. Integrated barbs engage panel edges with sufficient force to resist vibration-induced loosening while maintaining serviceability for maintenance and reconfiguration requirements.

Various cable capacity configurations accommodate single wire applications through large bundle management requirements, with specialized designs available for specific cable diameters and routing constraints. The spring steel construction ensures consistent performance across automotive temperature ranges while providing enhanced resistance to mechanical damage during installation and service operations.

Spring steel material properties deliver exceptional fatigue resistance under repeated flexing and vibration exposure commonly encountered in automotive and industrial applications. Temperature stability characteristics maintain clamping force consistency across extreme environmental conditions, from cold climate starting scenarios to underhood operating temperatures exceeding standard plastic material limits.

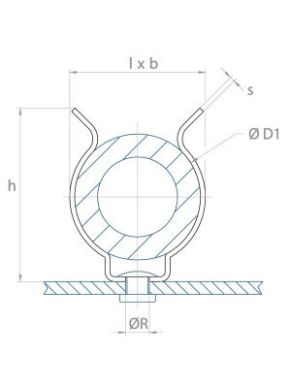

Plug Mount Metal Cable Clips with Dart Configuration

A-Raymond plug mount metal cable clips feature innovative dart-style retention mechanisms designed for through-hole panel installations where robust cable securing capability is required. These spring steel clips utilize expanding dart configurations that provide secure panel attachment through simple push-through installation while maintaining excellent pull-out resistance under mechanical stress.

The dart configuration enables installation from either front or rear panel access, accommodating various assembly line constraints and accessibility limitations commonly encountered in complex equipment assemblies. Self-expanding retention elements engage panel holes with sufficient force to resist displacement under vibration and mechanical shock while maintaining easy removal for service operations.

Multiple cable capacity variants accommodate applications ranging from single wire retention through large bundle management, with specialized designs available for specific cable routing requirements and environmental constraints. The plug mount design eliminates secondary fastening hardware while providing superior retention compared to conventional cable tie and mount combinations.

Spring steel construction ensures consistent retention force across temperature extremes while maintaining resistance to fatigue failure under repeated mechanical stress. Chemical resistance properties provide compatibility with automotive fluids, industrial solvents, and environmental contaminants commonly encountered in demanding service environments.

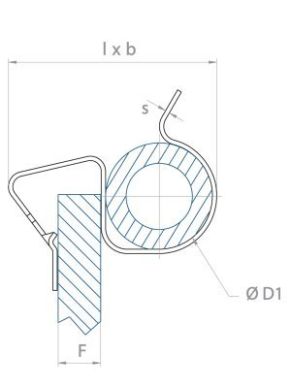

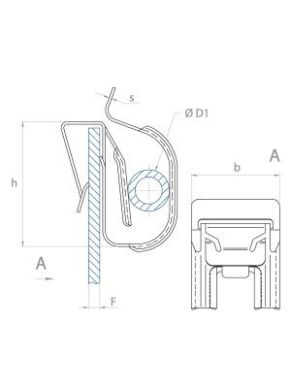

Heel-Toe Mount Metal Cable Clips for Enhanced Retention

A-Raymond heel-toe mount metal cable clips provide exceptional retention force through innovative locking mechanisms that engage panel holes with maximum security while maintaining tool-free installation characteristics. The heel-toe design enables clip positioning in mounting holes followed by forward pressure application that forces the heel element into locked position with superior pull-out resistance.

This mounting configuration provides enhanced security for critical cable routing applications where cable displacement could result in equipment malfunction or safety concerns. The heel-toe mechanism ensures positive engagement that resists loosening under extreme vibration and mechanical stress while maintaining accessibility for planned maintenance operations.

Variable cable capacity configurations accommodate diverse bundling requirements from single wire applications through large harness assemblies commonly encountered in automotive and industrial equipment. Specialized designs address specific routing constraints including tight radius applications and multiple cable diameter combinations within single installations.

The spring steel construction delivers consistent performance across environmental extremes while providing enhanced corrosion resistance compared to standard steel fasteners. Surface treatment options include various coating systems that enhance environmental protection for outdoor installations and chemically aggressive environments.

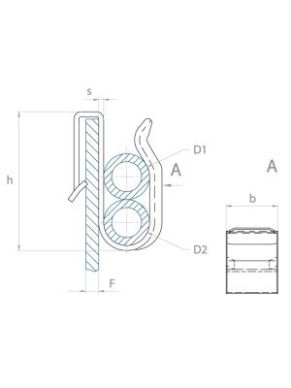

Bundle Capacity Metal Cable Clips for Large Harness Applications

A-Raymond bundle capacity metal cable clips are specifically engineered for large harness applications where multiple cables must be secured as unified assemblies. These robust spring steel clips feature enlarged retention areas and enhanced clamping mechanisms that accommodate substantial cable bundles while maintaining consistent retention force distribution across all contained cables.

The bundle design incorporates multiple retention points that prevent individual cable movement within secured assemblies while maintaining overall bundle flexibility required for dynamic applications. Enhanced spring steel construction provides sufficient clamping force for large diameter assemblies without compromising individual cable integrity or causing installation damage.

Various mounting configurations accommodate edge mount, plug mount, and specialized attachment requirements for large bundle applications. The design ensures even pressure distribution that prevents cable deformation while maintaining secure retention under mechanical stress and vibration exposure.

Specialized variants address automotive harness requirements including underhood applications where temperature extremes and environmental exposure demand enhanced performance characteristics. Industrial variants accommodate large control cable assemblies and power distribution harnesses commonly encountered in manufacturing equipment and machinery installations.

Swivel Mount Metal Cable Clips for Multidirectional Applications

A-Raymond swivel mount metal cable clips incorporate rotating mechanisms that enable optimal cable orientation relative to mounting surfaces while maintaining secure retention characteristics. These advanced spring steel clips feature modular swivel components that provide 360-degree rotation capability for complex routing requirements and dynamic assembly configurations.

The swivel mechanism accommodates changing cable orientations during equipment operation while maintaining consistent retention force and environmental protection. Specialized bearing surfaces ensure smooth rotation under load while resisting contamination and wear that could compromise long-term performance.

Multiple swivel configurations enable creation of complex routing networks through interconnected clip assemblies that adapt to evolving equipment requirements and maintenance accessibility needs. The modular approach reduces inventory requirements while providing maximum configuration flexibility for diverse applications.

Enhanced spring steel construction ensures swivel mechanism durability under repeated operation and environmental exposure. Specialized lubrication systems provide long-term operation capability while resisting contamination from automotive fluids and industrial chemicals.

Material Specifications and Environmental Performance

A-Raymond metal cable clips utilize high-grade spring steel formulations specifically selected for demanding wire management applications. The material specifications provide exceptional tensile strength, fatigue resistance, and temperature stability while maintaining consistent elastic properties throughout extensive service life under mechanical stress.

Heat treatment processes optimize spring steel characteristics for specific application requirements including enhanced fatigue resistance for high-vibration environments and improved corrosion resistance for outdoor installations. Specialized surface treatments provide additional environmental protection including zinc plating, phosphate coating, and specialized organic finishes.

Temperature performance specifications accommodate automotive underhood conditions ranging from extreme cold starting scenarios through sustained high-temperature operation. The spring steel construction maintains consistent clamping force across temperature extremes while resisting thermal cycling fatigue that can compromise retention characteristics.

Chemical resistance properties ensure compatibility with automotive fluids including engine oils, coolants, brake fluids, and cleaning solvents commonly encountered during service operations. Industrial variants provide enhanced resistance to hydraulic fluids, cutting oils, and specialized chemicals encountered in manufacturing environments.

Installation Guidelines and Performance Optimization

A-Raymond metal cable clips are designed for efficient installation using manual techniques that minimize specialized tooling requirements while ensuring consistent retention characteristics. Proper installation procedures maximize clip performance while preventing installation damage that could compromise long-term reliability.

Installation guidelines address proper clip selection based on cable bundle characteristics, panel material compatibility, and environmental requirements. Detailed procedures ensure optimal retention force application while preventing over-compression that could damage cables or compromise clip performance.

Quality installation practices include verification of retention force adequacy, proper cable routing to prevent chafing or stress concentration, and environmental protection considerations for outdoor or chemically aggressive installations. Maintenance guidelines address periodic inspection requirements and service procedures for dynamic applications.

Training resources support proper installation techniques while addressing common application challenges and troubleshooting procedures. Comprehensive documentation ensures consistent installation quality across production assembly operations while minimizing installation-related performance issues.

Custom Metal Cable Clip Solutions and Engineering Support

A-Raymond engineering capabilities enable development of custom metal cable clip solutions for specialized applications requiring unique mounting configurations, enhanced environmental protection, or specific performance characteristics. Custom development addresses unique cable routing requirements, specialized mounting constraints, and application-specific environmental challenges.

Collaborative engineering approaches ensure optimal clip specification for demanding applications while maintaining cost-effective manufacturing compatibility. Custom solutions include modified retention mechanisms, enhanced environmental protection features, specialized material formulations, and application-specific design modifications that address unique performance requirements.

Technical consultation services assist customers in selecting appropriate metal cable clip configurations for specific applications, considering factors such as vibration exposure, temperature requirements, chemical compatibility, and long-term durability expectations. Engineering support ensures optimal performance while minimizing total cost of ownership.

Prototype development services enable application validation and performance verification before production implementation. Testing capabilities include retention force verification, environmental exposure assessment, and long-term durability evaluation under representative service conditions.

Quality Standards and Manufacturing Excellence

A-Raymond metal cable clips are manufactured to demanding quality standards in facilities equipped with advanced automation and comprehensive quality control systems. Manufacturing processes incorporate precision stamping techniques, heat treatment procedures, and surface treatment applications that ensure consistent product quality and performance reliability.

Quality assurance protocols include dimensional verification, material property testing, and retention force validation to ensure compliance with engineering specifications. Environmental testing verifies performance characteristics under representative service conditions including temperature cycling, vibration exposure, and chemical compatibility assessment.

Industry certifications and compliance with automotive and industrial standards ensure that A-Raymond metal cable clips meet or exceed performance requirements for demanding applications. Comprehensive documentation supports specification processes while providing verification of performance characteristics for quality management systems.

Statistical process control procedures monitor manufacturing consistency while identifying potential quality issues before product shipment. Continuous improvement initiatives incorporate customer feedback and field performance data to enhance product design and manufacturing processes.

Technical Support and Application Assistance

Hall-Fast provides comprehensive technical support services for A-Raymond metal cable clip selection, application engineering, and performance optimization. Technical consultation includes wire management system design, product specification, installation guidance, and troubleshooting support for challenging applications.

Application assistance addresses unique cable routing challenges, environmental considerations, and performance optimization opportunities for demanding installations. Technical support services ensure optimal clip selection while addressing specific application requirements and constraints that may impact performance or installation procedures.

For technical assistance with A-Raymond metal cable clip selection or to discuss specific wire management requirements, customers can contact Hall-Fast's experienced technical support team. Additionally, Hall-Fast offers access to numerous other leading fastener brands through their comprehensive supplier network, ensuring customers receive optimal solutions for all cable management and fastening applications.

The extensive A-Raymond metal cable clip portfolio available through Hall-Fast provides robust, reliable solutions for demanding wire management challenges across automotive, industrial, and commercial applications. Free delivery is available on orders over £54.99 to UK mainland destinations, with next-day delivery options available for many standard products to support urgent project requirements and critical maintenance operations.

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price