Kemper

German Engineering Excellence in Welding Fume Control

Established in 1977 by Gerd Kemper in Germany, Kemper GmbH has dedicated over 45 years to developing and manufacturing superior welding fume extraction systems. As global leaders in clean air technology for metalworking environments, Kemper combines precision German engineering with continuous innovation to deliver extraction solutions that effectively protect workers while optimizing operational efficiency.

With international presence through subsidiaries and dealers worldwide, Kemper has built a reputation for exceptional quality, durability, and technical expertise in addressing the unique challenges of welding fume control. The company's commitment to occupational safety and environmental protection drives its development of increasingly effective filtration technologies and comprehensive air quality management systems.

Kemper's extensive experience in understanding the complex characteristics of welding fumes—including their composition, behaviour, and health impacts—has enabled the company to pioneer advancements in extraction efficiency, filtration performance, and system design that set industry standards for workplace air quality management.

Understanding the Dangers of Welding Fume Exposure

Composition and Health Risks of Welding Fumes

Welding fumes represent a complex mixture of ultra-fine particles and gases created during the welding process. These airborne contaminants contain various metal oxides, including iron, manganese, chromium, nickel, and zinc, among others. The exact composition depends on factors such as:

- Base materials being welded

- Welding consumables and electrodes used

- Welding processes employed (MIG, TIG, Stick, etc.)

- Presence of coatings or contaminants on the material

The health risks from welding fume exposure are significant and well-documented. Short-term exposure can cause immediate symptoms like irritation of the eyes, nose, throat, and respiratory tract, dizziness, nausea, and metal fume fever—a flu-like condition causing chills, fever, muscle aches, and fatigue that typically develops 4-12 hours after exposure.

Long-term exposure presents more serious health consequences, including:

- Chronic respiratory conditions like occupational asthma and bronchitis

- Pneumoconiosis (scarring of lung tissue)

- Chronic obstructive pulmonary disease (COPD)

- Increased susceptibility to lung infections

- Neurological effects from manganese exposure

- Kidney damage from certain metal exposures

- Increased cancer risk, particularly from hexavalent chromium and nickel compounds

Hexavalent Chromium: A Critical Concern

Hexavalent chromium (Cr(VI)) deserves special attention among welding fume contaminants due to its severe health implications. Created during welding of stainless steel and other chromium-containing alloys, hexavalent chromium is classified as a known human carcinogen, with exposure linked to lung cancer. Additionally, it can cause:

- Nasal and sinus cancers

- Kidney and liver damage

- Asthma and other respiratory conditions

- Skin ulceration and dermatitis

- Eye irritation and damage

The dangers of hexavalent chromium have led to increasingly strict regulatory limits, making high-efficiency extraction systems like those provided by Kemper essential for compliance and worker protection.

The Business Case for Effective Fume Extraction

Beyond the critical health considerations, implementing effective welding fume extraction delivers substantial business benefits:

- Reduced absenteeism and improved productivity

- Lower healthcare costs and workers' compensation claims

- Decreased equipment maintenance from reduced particulate contamination

- Enhanced compliance with tightening regulations

- Improved employee morale, recruitment, and retention

- Higher quality welds due to better visibility

- Extended equipment lifespan

- Lower facility cleaning costs

- Potential insurance premium reductions

Kemper extraction systems represent an investment in both worker health and business performance, with returns realized through multiple operational and financial benefits.

Comprehensive Kemper Extraction Solutions

Mobile Extraction Units

Kemper's mobile extraction units provide flexible solutions for changing workplace needs, workshops with diverse layouts, or facilities where permanent installations are impractical. These standalone units combine powerful extraction capability with mobility, offering appropriate solutions for various applications:

SmartMaster Series: Compact, entry-level mobile extractors ideal for occasional welding, small workshops, or educational settings. Features include:

- Single extraction arm configurations (typically 2-4m reach)

- Suitable for light to medium-duty applications

- Mechanical filter cleaning system

- Disposable filter cartridges

- Easy manoeuvrability with integrated wheels

ProfiMaster Series: Mid-range extraction units designed for regular professional use in small to medium workshops, offering:

- Single or dual extraction arm options

- Enhanced suction power for more intensive applications

- Larger filter surface area for extended operation

- Optional automatic filter cleaning

- Digital operating controls with filter saturation monitoring

MaxiFil Series: Advanced mobile extraction solutions for heavy-duty professional environments, featuring:

- High-performance motors with enhanced extraction capacity

- IFA W3 certification for high-alloy steel welding

- Automatic filter cleaning technology

- KemTex® ePTFE membrane filters for superior particle capture

- Extended filter life and reduced maintenance

- Digital control interfaces with programmable functions

These mobile units provide the flexibility to position extraction directly at the welding source, maximizing capture efficiency while allowing reconfiguration as workshop layouts or projects change.

Stationary Extraction Systems

For fixed workstations or consistent welding locations, Kemper offers stationary extraction solutions that provide reliable, dedicated fume control:

Wall-Mounted Systems: Space-saving extraction arms mounted directly to walls or support columns, available in various lengths (2-10m) and designs to suit different workspace configurations. These systems can be connected to:

- Individual filter units for single workstations

- Central extraction systems serving multiple workstations

- Direct exhaust systems (where permitted by regulations)

Filter-Cell Systems: Self-contained extraction and filtration units designed for integration with welding booths or fixed workstations. Key features include:

- Customizable extraction hood configurations

- High-capacity filter systems for extended operation

- Optional automatic filter cleaning

- Modular design allowing expansion as needs change

Filter-Table Solutions: Specialized downdraft tables that combine a working surface with integrated extraction, ideal for smaller workpieces and cutting operations. These systems offer:

- Built-in filtration with easy maintenance access

- Generous working surfaces with optional clamping systems

- Enhanced capture efficiency through downdraft design

- Available with optional back and side walls for improved containment

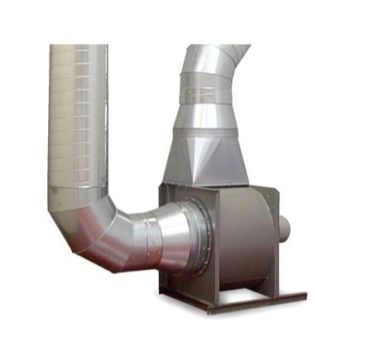

Centralized Extraction Systems

For larger facilities or multiple welding stations, Kemper's centralized extraction systems provide comprehensive air quality management with optimized efficiency:

Central Filter Systems: These engineered solutions connect multiple extraction points to a central filtration unit, offering:

- Economies of scale in filtration and energy consumption

- Consistent extraction performance across all workstations

- Automated filter cleaning and dust disposal

- Simplified maintenance concentrated at a single location

- Options for heat recovery to reduce energy costs

Custom-Engineered Solutions: For complex manufacturing environments, Kemper designs tailored systems addressing specific facility requirements:

- Integration with building management systems

- Customized ducting designed for optimal air flow

- Programmable operation aligned with production schedules

- Scalable designs accommodating future expansion

- Energy-efficient approaches minimizing operational costs

CleanAirTower: Ambient Air Filtration

As a complement to source extraction or for areas where source capture is challenging, Kemper's CleanAirTower provides efficient ambient air filtration:

- Effective removal of fine dust and smoke particles from general workspace air

- Implementation of the displacement ventilation principle (layered air concept)

- Available in various capacities to suit different space dimensions

- Optional integration with AirWatch monitoring systems

- Automatic filter cleaning technology

- Minimal floor space requirements

- Simple installation without extensive ducting

Digital Air Quality Management

Kemper's commitment to comprehensive air quality solutions extends to digital monitoring and management systems:

AirWatch: Continuous air quality monitoring system providing real-time data on particulate levels, with features including:

- Visual display of current air quality status

- Documentation of air quality trends over time

- Automatic activation of additional filtration when needed

- Integration with building management systems

- Compliance documentation capabilities

AirTracker: Individual workstation monitoring devices that provide immediate feedback on local air quality, helping ensure proper use of extraction equipment and identifying potential issues before they affect worker health.

Advanced Technology and Superior Performance

KemTex® ePTFE Membrane Filter Technology

At the heart of Kemper's exceptional filtration performance lies the proprietary KemTex® ePTFE membrane technology. These advanced filters feature:

- Surface filtration rather than depth filtration, preventing particle penetration into filter media

- Membrane structure with microscopic pores that capture even the smallest welding fume particles

- Efficiency rates exceeding 99.9% for particles as small as 0.1 micron

- Self-cleaning properties that maintain consistent airflow

- Extended service life compared to conventional filters

- Lower pressure drop, reducing energy consumption

- Durability in demanding industrial environments

This advanced filter technology enables Kemper systems to achieve W3 certification for extraction of high-alloy steel welding fumes, which contain the most hazardous hexavalent chromium compounds.

Automatic Filter Cleaning Systems

Kemper's commitment to maintaining optimal extraction performance is evident in their sophisticated filter cleaning technologies:

- Rotating nozzle cleaning systems that provide thorough filter regeneration

- Programmable cleaning cycles based on actual usage patterns

- Compressed air management minimizing consumption

- Controlled disposal of collected particulates

- Monitoring systems preventing operation with compromised filters

This automated approach ensures consistent extraction performance while minimizing maintenance requirements and extending filter life.

Energy Efficiency Innovations

Recognizing the significant energy requirements of extraction systems, Kemper has developed numerous technologies to optimize efficiency:

- Variable frequency drives adjusting motor speed to actual demand

- Automatic start/stop systems activated by welding arc detection

- Thermal insulation reducing heat loss in ducted systems

- Intelligent control systems optimizing multiple extraction points

- Heat recovery options for cold-climate installations

- Energy-saving standby modes during production breaks

These efficiency features significantly reduce the lifetime operating costs of Kemper systems while supporting sustainability goals.

Extraction Arm Technology

Kemper's extraction arms incorporate numerous design innovations that enhance performance and usability:

- Internal support structures that maximize airflow efficiency

- Smooth-operating joints maintaining position without drift

- 360° rotating extraction hoods for optimal positioning

- Integrated lighting options illuminating the work area

- Specialized hood designs maximizing capture efficiency

- Easy-to-operate dampers for flow adjustment

- Durable construction withstanding harsh industrial environments

Available in lengths from 2 to 10 meters and in various mounting configurations, Kemper's extraction arms provide the versatility to address virtually any welding application.

Industry-Specific Extraction Solutions

Metal Fabrication and Manufacturing

For general metal fabrication shops, Kemper offers scalable solutions addressing the varied extraction needs of these diverse environments:

- Combination systems accommodating multiple welding processes

- Flexible configurations adapting to changing production layouts

- Robust designs withstanding the demands of industrial environments

- Cost-effective approaches balancing performance with investment

- Expandable systems growing with business needs

Automotive Manufacturing and Supply Chain

The automotive sector's demanding production environments require specialized extraction solutions addressing high-volume welding operations:

- Integration with robotic welding cells

- High-capacity systems for intensive production schedules

- Custom hood designs for specific component geometries

- Compliance with automotive industry quality standards

- Consistent performance supporting production uptime requirements

Shipbuilding and Heavy Equipment Manufacturing

These industries present unique challenges with large-scale welding on massive components, often using high-strength and specialty alloys:

- Extended-reach extraction arms accessing difficult positions

- Mobile high-vacuum systems for confined space work

- Heavy-duty filtration handling intensive welding operations

- Specialized solutions for outdoor and semi-outdoor environments

- Systems capable of handling high-alloy steel welding

Aerospace and Precision Manufacturing

The aerospace sector's exacting standards and specialized materials demand extraction systems with exceptional performance:

- Ultra-high efficiency filtration for exotic metal welding

- Clean room compatible extraction solutions

- Specialized systems for aluminum and titanium welding

- Documentation capabilities supporting quality requirements

- Integration with precision manufacturing processes

Educational Institutions

Welding training facilities present unique requirements balancing educational needs with student safety:

- Flexible systems accommodating multiple learning stations

- Clear visibility for instructional observation

- Durable construction withstanding student use

- Demonstrable technology supporting safety education

- Cost-effective solutions within educational budgets

Regulatory Compliance and Safety Standards

Meeting OSHA Requirements

Kemper extraction systems are designed to help facilities comply with OSHA's increasingly stringent requirements for welding fume control:

- Solutions supporting compliance with Permissible Exposure Limits (PELs) for various metal fumes

- Documentation capabilities for regulatory inspections

- Systems addressing OSHA's emphasis on engineering controls over respiratory protection

- Compliance with OSHA ventilation standards

- Support for written respiratory protection programs

International Standards Compliance

For global operations, Kemper systems meet relevant international standards including:

- EN ISO 21904-1,-2,-3,-4 (Health and safety in welding and allied processes)

- ISO 15012 series standards for welding fume extraction equipment

- European CE marking requirements

- Country-specific workplace exposure regulations

- International certification for specialty applications (like W3 for high-alloy steels)

W3 Certification for High-Alloy Welding

Kemper's advanced filtration systems achieve the demanding W3 certification from Germany's Institute for Occupational Safety and Health (IFA), indicating:

- Suitability for extraction of high-alloy steel welding fumes (containing >30% nickel and chromium)

- Verified filtration efficiency exceeding 99% for the most hazardous fume particles

- Validated performance through rigorous independent testing

- Recirculation capability even with the most challenging fume types

- Compliance with the strictest international standards

Installation, Service and Maintenance

Professional System Design and Installation

Kemper's approach to system implementation ensures optimal performance through:

- Comprehensive site assessment identifying specific extraction requirements

- Airflow analysis ensuring adequate capture velocities

- Professional installation by trained technicians

- Commissioning and testing verifying system performance

- Operator training supporting proper system use

- Documentation for regulatory compliance

Ongoing Service and Support

To maintain peak performance throughout system life, Kemper provides:

- Preventative maintenance programs tailored to usage patterns

- Rapid response service minimizing operational disruptions

- Factory-trained technicians ensuring proper maintenance

- Original replacement parts maintaining system integrity

- Software updates for digital control systems

- Technical support for operational questions

Maintenance Best Practices

Proper maintenance ensures optimal extraction performance and system longevity:

- Regular filter inspection and replacement according to monitoring indicators

- Scheduled inspection of extraction arms and hoods for damage or wear

- Verification of automatic cleaning system operation

- Checking of dust collection containers and proper disposal of collected material

- Monitoring of airflow performance to detect potential issues early

- Inspection of ducting for possible leakage or damage

Return on Investment and Economic Benefits

Calculating Total Cost of Ownership

When evaluating welding fume extraction investments, Kemper helps customers understand the complete financial picture:

- Initial equipment and installation investment

- Energy consumption costs over expected system life

- Filter replacement and routine maintenance expenses

- Labor costs for system maintenance

- Potential savings from reduced heating/cooling with filtered air recirculation

- Productivity benefits from improved workplace conditions

- Regulatory compliance cost avoidance

- Reduced cleaning and equipment maintenance costs

- Worker health cost reductions

Financing and Support Options

To facilitate investment in worker health protection, Kemper offers:

- Flexible financing options spreading investment over time

- Leasing alternatives with maintenance inclusion

- Support in accessing applicable worker safety grants or incentives

- Trade-in programs when upgrading from older equipment

- Scalable implementation approaches allowing phased investment

Productivity Improvements

Beyond health protection, Kemper extraction systems deliver operational benefits:

- Reduced downtime from improved worker health and comfort

- Enhanced weld quality through better visibility

- Decreased equipment maintenance requirements

- Improved workshop cleanliness reducing time spent cleaning

- Enhanced worker satisfaction and retention

- Extended equipment lifespan in cleaner environments

Choosing the Right Kemper Extraction Solution

Assessment of Extraction Requirements

Selecting the optimal Kemper solution begins with a thorough evaluation of extraction needs:

- Welding processes used (MIG, TIG, Stick, etc.)

- Materials being welded (mild steel, stainless, aluminum, etc.)

- Duty cycle and intensity of welding operations

- Physical layout of welding areas

- Mobility requirements for changing workflows

- Future expansion possibilities

- Specific regulatory requirements for your industry

- Budget considerations (initial and operating)

Mobile vs. Stationary vs. Centralized Systems

The choice between extraction system types depends on several factors:

- Fixed vs. changing welding locations

- Number of simultaneous welding operations

- Available space for equipment installation

- Budget constraints and long-term expansion plans

- Facility ownership vs. leasing considerations

- Need for flexibility in production layout

- Energy efficiency priorities

System Sizing and Specification

Proper sizing ensures effective capture while optimizing investment:

- Airflow requirements based on welding processes

- Extraction arm quantity, length, and positioning

- Filter capacity aligned with production volume

- Motor power matched to system resistance

- Control options appropriate for operational needs

- Integration requirements with existing systems or facilities

Experience the Kemper Difference in Welding Fume Extraction

For over four decades, Kemper has set the standard for effective welding fume extraction through German-engineered solutions combining superior filtration performance, operational efficiency, and durable construction. The company's comprehensive approach addresses not only immediate health protection needs but also long-term operational considerations including energy efficiency, maintenance requirements, and adaptability to changing production demands.

By investing in Kemper extraction technology, facilities gain both world-class protection for their workforce and significant operational advantages through improved air quality. From compact mobile units to facility-wide centralized systems, Kemper provides solutions tailored to specific welding applications, spatial constraints, and budgetary considerations.

Discover how Kemper's welding fume extraction expertise can transform your workplace air quality while enhancing productivity, regulatory compliance, and operational efficiency. Contact our team today for a comprehensive assessment of your extraction requirements and a customized solution designed for your specific welding applications.

Starting at £4,618.80 £3,849.00

- Call For Price

Starting at £629.40 £524.50

Starting at £554.78 £462.32

Starting at £1,667.57 £1,389.64

- Call For Price

- Call For Price

- Call For Price

- £892.26 £743.55

Starting at £1,874.08 £1,561.73