Hall-Fast, based in Mansfield, Nottinghamshire, offers a comprehensive range of A-Raymond shaft clips and nuts engineered for demanding fastening applications across automotive, industrial, and commercial sectors. As an authorised UK distributor of A-Raymond fastening solutions, Hall-Fast provides immediate access to precision-manufactured shaft retainers, snap-in nuts, snap-on nuts, and specialized fastening components that deliver superior retention force, vibration resistance, and long-term durability for critical assembly applications.

Professional Shaft Clips and Nuts for Industrial Assembly

A-Raymond shaft clips and nuts represent advanced fastening technology specifically engineered for applications requiring secure shaft retention, efficient panel attachment, and reliable threaded connections. These precision-manufactured components combine superior material properties with innovative design features to deliver reliable fastening performance in automotive assemblies, industrial equipment, and demanding applications where standard fasteners cannot provide adequate retention or installation convenience.

The comprehensive shaft clips and nuts portfolio encompasses metal snap-in nuts for metric and self-tapping applications, metal snap-on nuts with universal compatibility, plastic snap-in nuts for specialized mounting requirements, shaft retainers for smooth and grooved shaft applications, cage nuts for rack mounting systems, and Palnut push-on fasteners for decorative and functional applications. Each component variant utilizes advanced materials and manufacturing processes that ensure consistent performance across extreme operating conditions.

Metal Snap-In Nuts for Secure Panel Fastening

A-Raymond metal snap-in nuts provide robust fastening solutions for applications requiring secure threaded connections in panel assemblies where rear access is limited or unavailable. These precision-stamped nuts feature spring steel legs that snap into panel holes and self-retain in position, eliminating the need for welding, riveting, or complex installation procedures.

The snap-in design accommodates both metric bolts and self-tapping screws, providing versatile fastening capability for diverse assembly requirements. Metric variants offer precise threading compatibility with standard metric bolt specifications commonly used in automotive and industrial applications, while self-tapping versions accommodate sheet metal screws and specialized fastening requirements.

Cage nut configurations provide enhanced retention characteristics for rack mounting applications and equipment installations requiring frequent assembly and disassembly operations. The spring steel cage design ensures proper thread alignment while providing secure retention that resists loosening under vibration and mechanical stress.

Advanced manufacturing processes ensure consistent thread quality, dimensional accuracy, and retention force characteristics throughout production volumes. Heat treatment procedures optimize spring steel properties for enhanced fatigue resistance and long-term reliability under repeated assembly cycles.

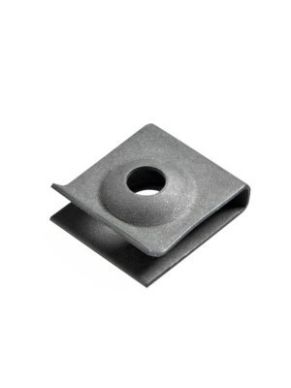

Metal Snap-On Nuts for Universal Panel Applications

A-Raymond metal snap-on nuts feature innovative slide-on designs that provide efficient panel edge mounting for applications requiring rapid installation and secure threaded connections. These universal nuts slide onto panel edges and over panel holes, self-retaining in screw-receiving position while accommodating variable panel thickness specifications.

The snap-on design prevents nut rotation during screw installation while eliminating the risk of thread freezing commonly encountered with conventional nut and bolt assemblies. Anti-creeping mechanisms enable mounting on plastic panels while correcting alignment with holes, ensuring proper thread engagement and optimal fastening performance.

Universal configurations accommodate both metric bolts and self-tapping screws while providing adjustable retention characteristics for different panel thickness ranges. Retaining tab versions prevent nut movement during transport and pre-assembly operations, making them ideal for automated assembly processes and kit packaging applications.

The spring steel construction maintains consistent clamping force across temperature variations while providing enhanced resistance to corrosion and environmental exposure. Surface treatment options include various coating systems that enhance durability and appearance while maintaining electrical conductivity for grounding applications.

Plastic Snap-In Nuts for Specialized Applications

A-Raymond plastic snap-in nuts provide lightweight, corrosion-resistant fastening solutions for applications requiring electrical insulation, chemical resistance, and cost-effective assembly. These precision-moulded nuts feature designs optimized for oblong holes, square holes, and specialized panel configurations commonly encountered in electrical enclosures and electronic equipment.

The plastic construction provides excellent electrical insulation properties essential for electrical applications while eliminating concerns about galvanic corrosion and electromagnetic interference. Various thermoplastic formulations address specific environmental requirements including temperature resistance, chemical compatibility, and UV stability for outdoor applications.

Oblong hole configurations accommodate panel tolerance variations and thermal expansion while maintaining secure thread engagement. Square hole variants provide anti-rotation characteristics essential for applications requiring consistent fastener orientation and torque transmission.

Advanced injection moulding processes ensure consistent dimensional accuracy and thread quality while providing cost-effective manufacturing for high-volume applications. Material options include nylon, acetal, and specialized compounds selected for specific performance requirements and environmental conditions.

Shaft Retainers for Smooth and Grooved Shaft Applications

A-Raymond shaft retainers provide efficient solutions for securing smooth and grooved shafts in panels and structural assemblies where traditional fastening methods prove impractical or space-constrained. These specialized clips accommodate various shaft configurations while providing tool-free installation and reliable retention characteristics.

Rectangular push-on retainers are designed for smooth shaft applications where the clip must be pushed onto the shaft from the top using manual force or magnetic cylindrical tools. The design accommodates both metal and plastic shafts while providing secure retention suitable for light-duty applications requiring easy removal for maintenance operations.

Circular push-on retainers offer enhanced retention characteristics for applications requiring higher performance compared to standard versions. Heavy-duty variants provide increased holding force for demanding applications while maintaining tool-free installation procedures and compact space requirements.

C-clip retainers for grooved shafts provide positive mechanical retention through engagement with machined grooves. Various designs accommodate grooves at any position on the shaft or specific distances from shaft ends, enabling flexible design integration while ensuring secure shaft retention under mechanical stress and vibration.

Speed Nuts and Palnut Fastening Systems

A-Raymond Speed Nuts provide efficient fastening solutions for applications requiring reduced installation torque compared to standard hex nuts while maintaining secure panel-to-panel connections. These specialized nuts can be installed before painting operations to prevent thread contamination while providing reliable performance in small electrical and mechanical equipment applications.

The Speed Nut design requires less installation torque than conventional hex nuts while providing superior resistance to vibration-induced loosening. Thread configurations accommodate standard screw specifications while providing enhanced retention characteristics suitable for applications where space limitations restrict access for conventional fastening methods.

Palnut stamped nuts offer versatile push-on fastening solutions that lock tightly with studs while preventing accidental disassembly. These washer-style nuts feature integrated washers that compensate for component build variations while providing all-in-one solutions that replace multiple smaller parts.

Decorative Palnut fasteners hide unattractive shaft, stud, or rod ends while providing dependable, vibration-resistant assembly characteristics. Available in metal and plastic variants with various colour options, these fasteners enhance product appearance while maintaining reliable fastening performance suitable for toys, garbage cans, wheels, coolers, and consumer products.

Advanced Material Specifications and Heat Treatment

A-Raymond shaft clips and nuts utilize high-grade materials specifically selected for demanding fastening applications. Spring steel variants provide exceptional tensile strength, elastic memory, and fatigue resistance while maintaining consistent performance characteristics throughout extensive service life under mechanical stress and environmental exposure.

Heat treatment processes optimize material properties for specific application requirements including enhanced fatigue resistance for high-vibration environments and improved corrosion resistance for outdoor installations. Austempering procedures provide superior hardness characteristics while maintaining toughness and impact resistance.

Thermoplastic variants utilize advanced polymer formulations including nylon, acetal, polyethylene, and specialized compounds selected for specific environmental and performance requirements. Material selection ensures optimal compatibility with application conditions while providing cost-effective manufacturing and long-term reliability.

Surface treatment options include zinc plating, phosphate coating, and specialized organic finishes that enhance corrosion resistance while maintaining electrical conductivity for grounding applications. Quality control procedures verify material properties and treatment effectiveness throughout manufacturing processes.

Installation Procedures and Performance Optimization

A-Raymond shaft clips and nuts are designed for efficient installation using manual techniques that minimize specialized tooling requirements while ensuring consistent retention characteristics across production assembly operations. Proper installation procedures maximize component performance while preventing installation damage that could compromise long-term reliability.

Tool-free installation methods enable rapid deployment during assembly operations while maintaining consistent quality results. Snap-in nuts require simple push-through operation that engages spring legs for secure panel attachment, while snap-on nuts slide over panel edges with positive retention engagement.

Shaft retainer installation procedures accommodate various access constraints and assembly requirements. Push-on variants utilize manual force or magnetic tools for rapid installation, while C-clips require lateral engagement with shaft grooves for positive mechanical retention.

Quality installation practices include verification of proper engagement, appropriate retention force, and correct orientation for optimal performance. Training resources support proper installation techniques while addressing common application challenges and troubleshooting procedures for complex assembly scenarios.

Vibration Resistance and Mechanical Performance

A-Raymond shaft clips and nuts are specifically engineered to provide superior vibration resistance compared to conventional fastening methods, making them ideal for automotive applications, industrial machinery, and equipment installations where mechanical stress and vibration exposure are significant concerns.

Spring steel construction maintains consistent retention force under dynamic loading conditions while resisting loosening and displacement. Self-retaining characteristics eliminate the need for secondary retention methods while providing comprehensive resistance to vibration-induced movement and thread loosening.

Advanced design features including anti-creeping mechanisms, positive mechanical engagement, and optimized spring characteristics ensure reliable performance under extreme vibration conditions commonly encountered in automotive underhood applications and industrial machinery installations.

Testing protocols verify performance under representative vibration conditions including automotive road simulation, industrial machinery operation, and specialized applications requiring enhanced mechanical durability. Quality assurance procedures ensure consistent performance characteristics while maintaining compatibility with automated assembly processes.

Custom Fastening Solutions and Engineering Support

A-Raymond engineering capabilities enable development of custom shaft clip and nut solutions for specialized applications requiring unique configurations, enhanced environmental protection, or specific performance characteristics. Custom development addresses unique fastening requirements and application-specific challenges not addressed by standard product offerings.

Collaborative engineering approaches ensure optimal component specification for demanding applications while maintaining cost-effective manufacturing compatibility. Custom solutions include modified retention mechanisms, enhanced environmental protection features, specialized material formulations, and application-specific design modifications.

Technical consultation services assist customers in selecting appropriate shaft clip and nut configurations for specific applications, considering factors such as panel materials, vibration exposure, temperature requirements, chemical compatibility, and long-term durability expectations.

Prototype development services enable application validation and performance verification before production implementation. Testing capabilities include retention force verification, environmental exposure assessment, vibration resistance evaluation, and long-term durability testing under representative service conditions.

Quality Standards and Manufacturing Excellence

A-Raymond shaft clips and nuts are manufactured to demanding quality standards in facilities equipped with advanced stamping and moulding equipment and comprehensive quality control systems. Manufacturing processes incorporate precision forming techniques, heat treatment procedures, and material verification that ensure consistent product quality and performance reliability.

Quality assurance protocols include dimensional verification, material property testing, and retention force validation to ensure compliance with engineering specifications and industry standards. Environmental testing verifies performance characteristics under representative service conditions including temperature cycling, vibration exposure, and chemical compatibility assessment.

Industry certifications and compliance with automotive and industrial standards ensure that A-Raymond shaft clips and nuts meet or exceed performance requirements for demanding applications. Comprehensive documentation supports specification processes while providing verification of performance characteristics for quality management systems.

Statistical process control procedures monitor manufacturing consistency while identifying potential quality issues before product shipment. Continuous improvement initiatives incorporate customer feedback and field performance data to enhance product design and manufacturing processes.

Technical Support and Application Assistance

Hall-Fast provides comprehensive technical support services for A-Raymond shaft clip and nut selection, application engineering, and performance optimization. Technical consultation includes fastening system design, product specification, installation guidance, and troubleshooting support for challenging applications requiring specialized solutions.

Application assistance addresses unique fastening challenges, environmental considerations, and performance optimization opportunities for demanding installations. Technical support services ensure optimal component selection while addressing specific application requirements and constraints that may impact performance or installation procedures.

For technical assistance with A-Raymond shaft clip and nut selection or to discuss specific fastening requirements, customers can contact Hall-Fast's experienced technical support team. Additionally, Hall-Fast offers access to numerous other leading fastener brands through their comprehensive supplier network, ensuring customers receive optimal solutions for all fastening applications.

The extensive A-Raymond shaft clips and nuts portfolio available through Hall-Fast provides robust, reliable solutions for demanding fastening challenges across automotive, industrial, and commercial applications. Free delivery is available on orders over £54.99 to UK mainland destinations, with next-day delivery options available for many standard products to support urgent project requirements and critical maintenance operations requiring immediate component availability.

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price