Hall-Fast, based in Mansfield, Nottinghamshire, offers a comprehensive range of A-Raymond cable ties designed for professional wire management and cable bundling applications across automotive, industrial, and commercial sectors. As an authorised UK distributor of A-Raymond fastening solutions, Hall-Fast provides immediate access to innovative cable tie technologies that combine superior material properties with advanced design features to deliver reliable, long-lasting cable management performance.

Professional A-Raymond Cable Tie Solutions for Industrial Applications

A-Raymond cable ties represent advanced wire management technology engineered to meet the demanding requirements of modern industrial and automotive applications. These precision-manufactured cable ties feature enhanced material specifications, optimized tensile strength characteristics, and specialized design elements that ensure reliable cable bundling performance across diverse environmental conditions and mechanical stress scenarios.

The comprehensive A-Raymond cable tie portfolio encompasses standard cable ties for general bundling applications, re-openable cable ties for maintenance-friendly installations, specialized mounting variations for specific attachment requirements, and custom solutions designed to address unique application challenges. Each cable tie variant incorporates advanced material science and manufacturing processes that deliver consistent performance while maintaining cost-effective production compatibility.

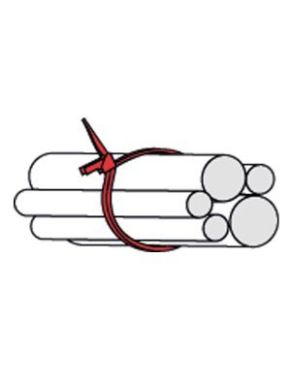

Standard A-Raymond Cable Ties for General Bundling Applications

A-Raymond standard cable ties provide reliable, cost-effective solutions for general cable bundling requirements across industrial, automotive, and commercial applications. These cable ties feature high-quality nylon 6/6 construction that delivers excellent tensile strength, temperature resistance, and environmental durability while maintaining consistent installation characteristics throughout production assembly operations.

The standard cable tie design incorporates precision-moulded locking mechanisms that ensure secure bundle retention while providing smooth installation characteristics that minimize operator fatigue during high-volume assembly operations. Various length and width configurations accommodate cable bundle sizes ranging from small wire groups to large harness assemblies commonly encountered in automotive and industrial equipment.

Temperature-resistant formulations maintain mechanical properties across automotive underhood temperature ranges, while UV-stabilized variants provide enhanced performance for outdoor installations and applications requiring extended exposure to sunlight and environmental conditions. Chemical resistance properties ensure compatibility with common automotive fluids, industrial solvents, and cleaning agents encountered in manufacturing environments.

Re-Openable Cable Ties for Maintenance-Friendly Installations

A-Raymond re-openable cable ties feature innovative locking mechanisms that enable multiple installation and removal cycles without compromising bundle security or cable tie integrity. These maintenance-friendly cable ties are specifically designed for applications requiring frequent access, configuration changes, or periodic maintenance operations where permanent bundling solutions prove impractical.

The re-openable design incorporates specialized release mechanisms that can be operated manually or with simple tools, enabling quick cable access without cutting or replacing cable ties. This feature significantly reduces maintenance costs and downtime while providing flexibility for evolving cable routing requirements in dynamic industrial environments.

Enhanced material specifications ensure that re-openable cable ties maintain consistent locking force and retention characteristics throughout multiple use cycles. The design accommodates various bundle sizes and configurations while providing the same environmental resistance and mechanical performance characteristics as standard cable tie variants.

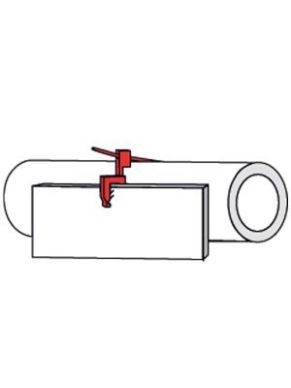

Edge Mounting Cable Ties for Panel Edge Applications

A-Raymond edge mounting cable ties integrate cable bundling functionality with panel edge attachment capability, creating comprehensive wire management solutions that eliminate the need for separate mounting hardware. These specialized cable ties feature integrated panel clips that provide secure attachment to panel edges without requiring pre-drilled holes or secondary fastening devices.

The edge mounting design incorporates spring steel retention elements that ensure reliable panel attachment while accommodating panel thickness variations commonly encountered in industrial equipment and automotive assemblies. Barb configurations provide enhanced retention force that resists vibration-induced loosening while maintaining easy installation characteristics.

Various panel edge configurations accommodate different material types including sheet metal, plastic panels, and composite materials. The integrated approach reduces component count and assembly time while providing superior cable organization compared to separate cable ties and mounting hardware combinations.

Plug Mounting Cable Ties for Through-Hole Applications

A-Raymond plug mounting cable ties feature integrated mounting bases designed for through-hole panel attachment, providing secure cable bundling capability in applications where panel holes are available or can be incorporated into design specifications. These cable ties eliminate the need for separate mounting hardware while providing robust attachment suitable for high-vibration environments.

The plug mounting design incorporates dart-style retention mechanisms that expand during installation to provide secure panel attachment with excellent pull-out resistance. Various hole diameter compatibilities ensure appropriate selection for specific panel configurations, from thin electrical enclosures to heavy-duty industrial equipment housings.

Installation requires simple push-through operation that can be performed manually or with basic tools, enabling rapid deployment during production assembly while maintaining consistent retention characteristics. The integrated approach simplifies inventory management and reduces assembly complexity compared to separate cable tie and mounting hardware combinations.

Stud Mounting Cable Ties for Threaded Applications

A-Raymond stud mounting cable ties integrate cable bundling functionality with threaded stud attachment capability, creating efficient solutions for applications where stud mounting points are available or preferred for specific installation requirements. These cable ties feature female threading or snap-on mechanisms that provide secure attachment to metric or imperial studs.

The stud mounting configuration eliminates vibration-induced loosening while providing robust cable support suitable for automotive underhood applications and industrial machinery where mechanical stress and environmental exposure require enhanced retention characteristics. Various stud diameter compatibilities accommodate standard threading specifications across automotive and industrial applications.

Spring steel construction elements ensure consistent clamping force across temperature variations and mechanical stress cycles commonly encountered in demanding applications. The integrated design reduces component count while providing superior retention compared to traditional cable tie and mounting hardware combinations.

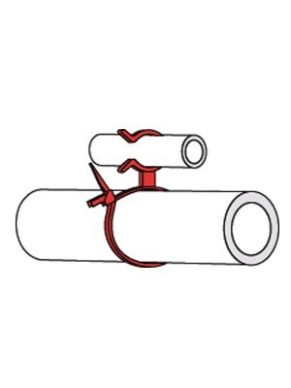

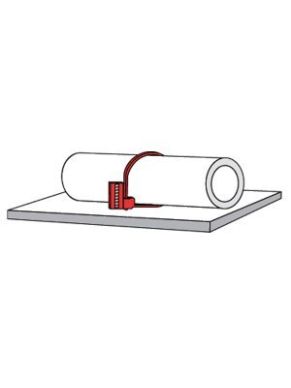

Tube Mounting Cable Ties for Specialized Applications

A-Raymond tube mounting cable ties provide specialized solutions for applications requiring cable attachment to existing tubes, pipes, or cylindrical structures. These cable ties feature integrated mounting mechanisms designed to secure cable bundles to round or oval surfaces without requiring panel holes or separate mounting hardware.

The tube mounting design incorporates curved retention elements that conform to cylindrical surfaces while providing secure cable attachment. Various tube diameter compatibilities ensure appropriate selection for different pipe sizes and mounting configurations commonly encountered in HVAC systems, hydraulic assemblies, and industrial piping applications.

Swivel mechanisms enable optimal cable orientation relative to tube mounting surfaces, accommodating complex routing requirements while maintaining secure attachment. The design provides vibration resistance suitable for applications where mechanical stress and environmental exposure require enhanced performance characteristics.

Advanced Material Specifications and Environmental Performance

A-Raymond cable ties utilize advanced material formulations specifically engineered for demanding automotive and industrial applications. High-quality nylon 6/6 construction provides excellent tensile strength, impact resistance, and temperature stability while maintaining consistent installation characteristics across various environmental conditions.

UV-stabilized formulations prevent degradation under extended sunlight exposure, making these cable ties suitable for outdoor installations and automotive exterior applications. Chemical resistance properties ensure compatibility with automotive fluids, industrial solvents, hydraulic oils, and cleaning agents commonly encountered in manufacturing and service environments.

Temperature performance specifications accommodate automotive underhood conditions, industrial machinery operating environments, and specialized applications requiring enhanced thermal stability. Low-temperature flexibility ensures reliable performance in cold climate installations while high-temperature resistance maintains mechanical properties under elevated operating conditions.

Custom Cable Tie Solutions and Engineering Support

A-Raymond engineering capabilities enable development of custom cable tie solutions for specialized applications requiring unique mounting configurations, enhanced environmental protection, or specific performance characteristics. Custom development services address unique bundling requirements, specialized material compatibility needs, and application-specific design challenges.

Collaborative engineering approaches ensure optimal cable tie specification for specific applications while maintaining cost-effective manufacturing compatibility. Custom solutions include modified mounting mechanisms, enhanced environmental protection features, specialized material formulations, and application-specific design modifications.

Technical consultation services assist customers in selecting appropriate cable tie configurations for specific applications, considering factors such as bundle size, environmental requirements, mounting constraints, and maintenance accessibility. Engineering support ensures optimal performance while minimizing total cost of ownership across product lifecycles.

Installation Guidelines and Best Practices

A-Raymond cable ties are designed for efficient installation using manual techniques that minimize labour requirements and specialized tooling needs. Proper installation practices ensure optimal performance while maintaining consistent bundle security across production assembly operations.

Installation guidelines include appropriate cable tie selection based on bundle size and application requirements, proper tensioning techniques that avoid over-tightening or cable damage, and verification procedures that ensure secure attachment and appropriate retention force. Quality installation practices maximize cable tie performance while maintaining serviceability for future maintenance operations.

Training resources and technical documentation support proper installation techniques while addressing common application challenges and troubleshooting procedures. Comprehensive installation guidelines ensure reliable performance across diverse applications while minimizing installation-related issues.

Quality Standards and Performance Testing

A-Raymond cable ties are manufactured to exacting quality standards in facilities equipped with advanced automation and comprehensive quality control systems. Manufacturing processes incorporate precision moulding techniques, material verification procedures, and performance testing protocols that ensure consistent product quality and reliability.

Performance testing includes tensile strength verification, environmental resistance evaluation, and long-term durability assessment under representative application conditions. Quality assurance procedures verify dimensional accuracy, material properties, and installation characteristics while ensuring compatibility with standard cable management practices.

Industry certifications and compliance with automotive and industrial standards ensure that A-Raymond cable ties meet or exceed performance requirements for demanding applications. Comprehensive documentation supports specification processes while providing verification of performance characteristics for quality management systems.

Technical Support and Application Assistance

Hall-Fast provides comprehensive technical support services for A-Raymond cable tie selection, application engineering, and performance optimization. Technical consultation includes cable management system design, product specification, installation guidance, and troubleshooting support for specific applications.

Application assistance addresses unique bundling challenges, environmental considerations, and performance optimization opportunities. Technical support services ensure optimal cable tie selection while addressing specific application requirements and constraints that may impact performance or installation procedures.

For technical assistance with A-Raymond cable tie selection or to discuss specific wire management requirements, customers can contact Hall-Fast's experienced technical support team. Additionally, Hall-Fast offers access to numerous other leading fastener brands through their comprehensive supplier network, ensuring customers receive optimal solutions for all cable management and fastening applications.

The extensive A-Raymond cable tie portfolio available through Hall-Fast provides reliable, cost-effective solutions for modern wire management challenges across automotive, industrial, and commercial applications. Free delivery is available on orders over £54.99 to UK mainland destinations, with next-day delivery options available for many standard products to support urgent project requirements.

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price

- Call For Price